An authorized KAESER service representative will support you in determining appropriate in‐

tervals and provide information on the possibilities of oil analysis.

➤ Please observe national regulations regarding the use of cooling oil in oil-injected screw com‐

pressors.

➤ Check operating conditions and adjust intervals as necessary.

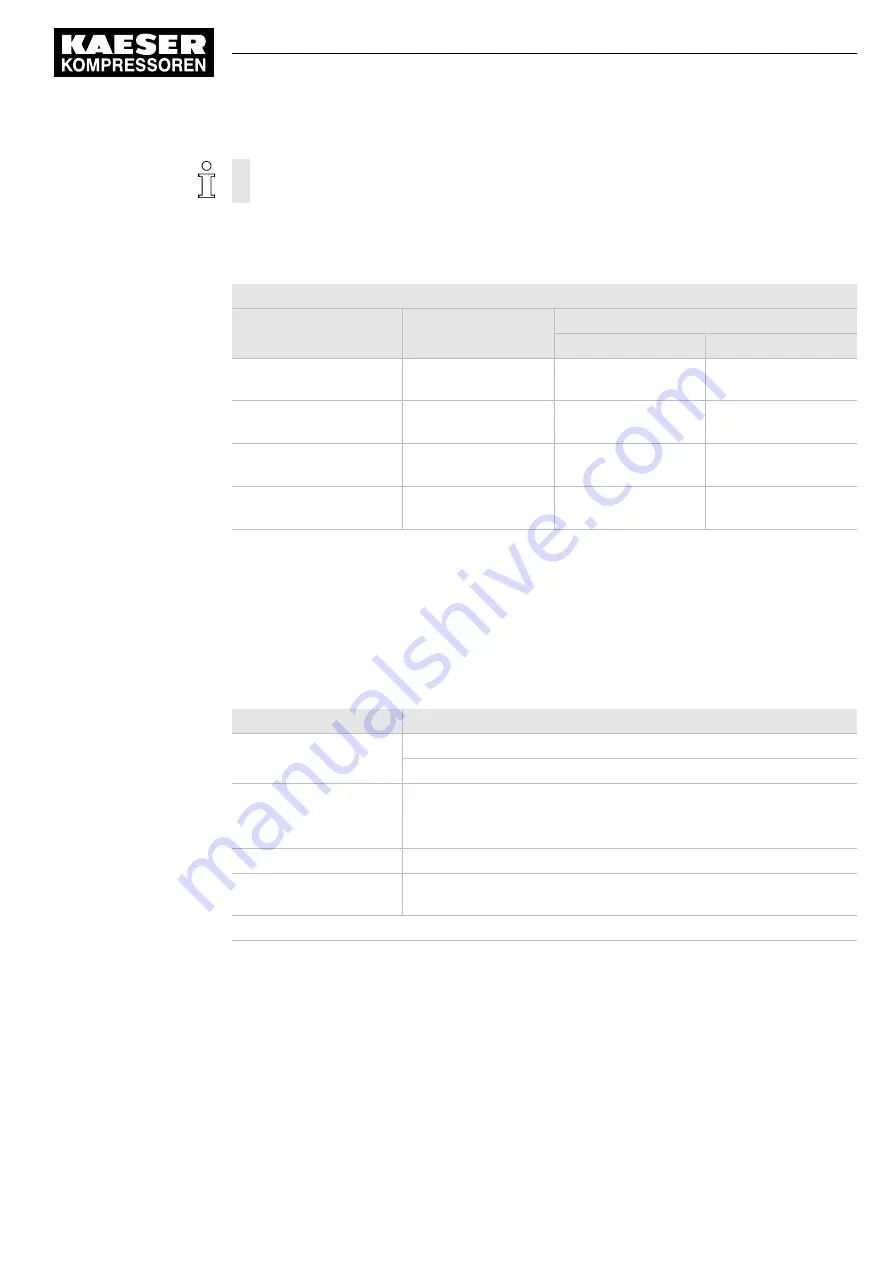

KAESER LUBRICANTS

SIGMA Lubricant

Description

Maximum Recommended Change Interval

First oil change

Subsequent oil change

M-460

ISO 46 Semi-Synthetic

Lubricant

2000 Hours

3000 Hours

S-460

ISO 46 Synthetic Lu‐

bricant

6000 Hours

8000 Hours

S-680

ISO 68 Synthetic Lu‐

bricant

6000 Hours

8000 Hours

FG-460

ISO 46 Food Grade

Synthetic Fluid

2000 Hours

3000 Hours

Tab. 37 Oil change intervals lubricants

10.2.5 Regular service tasks

The table below lists service tasks required.

➤ Only an authorized KAESER service representative should carry out service work.

➤ Have service tasks carried out punctually, taking ambient and operating conditions into ac‐

count.

Interval

Service task

Display:

SIGMA CONTROL 2

Service valves.

Replace the compressor drive motor bearings.

Up to 36000 h

Every 6 years at the lat‐

est.

Have plastic pipes and hose lines replaced.

Up to 36000 h

Replace the control cabinet fan.

After 20 years at the lat‐

est

Replace safety-relevant components of the safety devices.

h = operating hours

Tab. 38 Regular service tasks

10.3 Cooler: Cleaning or Renewing the Filter Mats

The filter mats help to keep the cooler clean. If the filter mats are clogged, adequate cooling of the

components is no longer ensured.

10 Maintenance

10.3 Cooler: Cleaning or Renewing the Filter Mats

9_5875 33 USE

Operator Manual Screw Compressor

SM Tri-Voltage, SIGMA CONTROL 2

57