In frequency-controlled compressors (SFC) the oil level indicator is only accurate when the

machine is running at or near maximum speed.

The lower the pressure at the compressed air outlet, the higher the speed.

Precondition The machine has been running at least 5 minutes under LOAD.

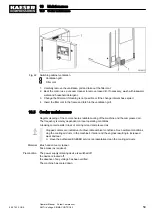

Fig. 27 Checking the cooling oil level

1

Minimum oil level

2

Maximum oil level

3

Optimum oil level

➤ Check the oil level with machine running under LOAD.

Result As soon as the minimum level is reached: Replenish the cooling oil.

10.14 Venting the machine (de-pressurizing)

Venting takes place in three stages:

■ Isolate the compressor from the air system.

■ Vent the oil separator tank.

■ Manually vent the air cooler.

The machine must be isolated from the compressed air network and completely vented be‐

fore undertaking any work on the pressure system.

Material The maintenance hose with hose coupling and shut-off valve needed for venting is stowed beneath

the oil separator tank.

Precondition The power supply disconnecting device is switched off,

The device is locked off,

A check has been made that no voltage is present.

Escaping oil mist is damaging to health.

➤ Do not direct the maintenance hose at persons while venting.

➤ Do not inhale the oil mist.

10 Maintenance

10.14 Venting the machine (de-pressurizing)

9_5875 33 USE

Operator Manual Screw Compressor

SM Tri-Voltage, SIGMA CONTROL 2

65