2. Slowly open the shut-off valve

7

to release pressure.

3. Disconnect the male hose fitting

6

and close the shut-off valve

7

.

10.15 Replenishing the cooling oil

The machine must be isolated from the compressed air network and completely vented be‐

fore undertaking any work on the pressure system.

Material The maintenance hose with hose coupling and shut-off valve needed for venting is stowed beneath

the oil separator tank.

Precondition The power supply disconnecting device is switched off,

The device is locked off,

A check has been made that no voltage is present.

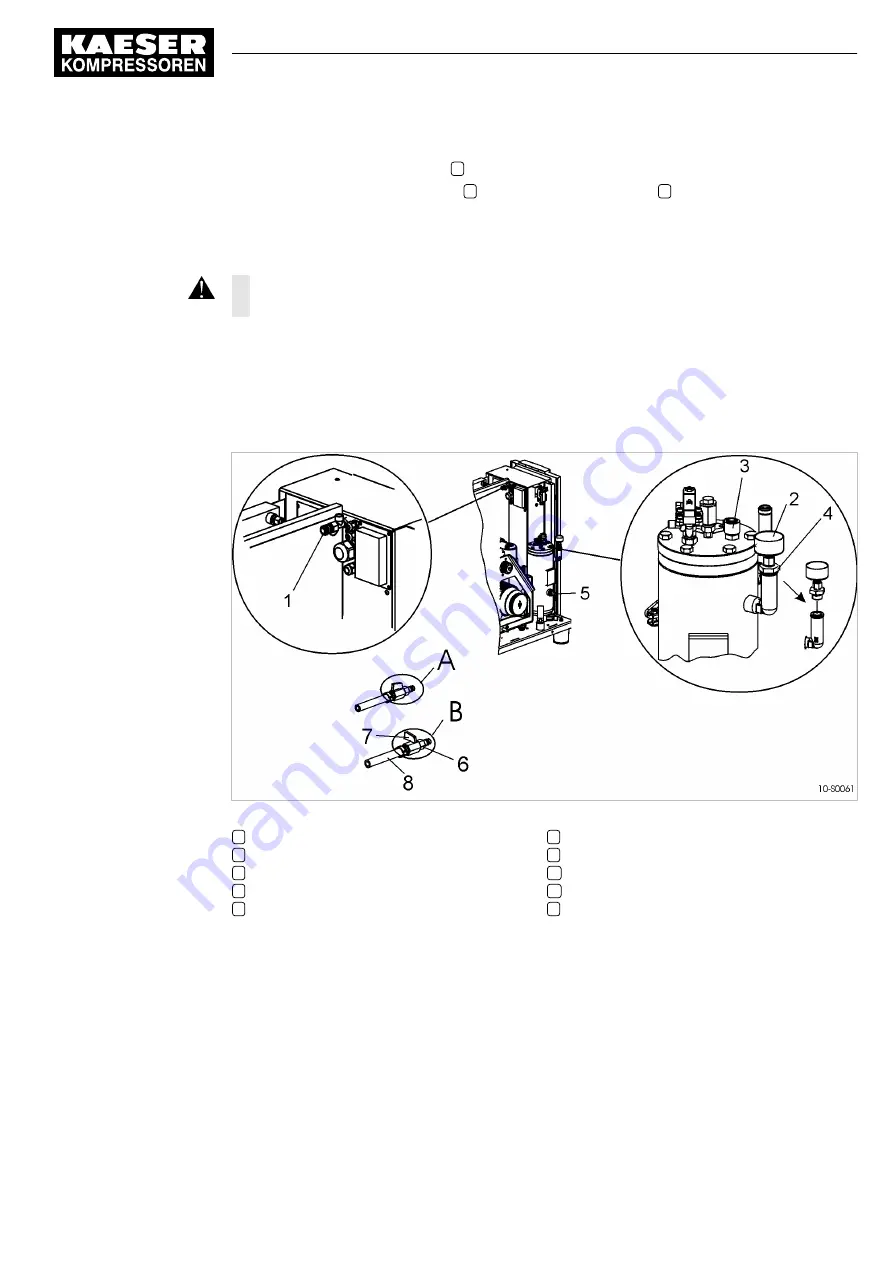

Fig. 29 Replenishing the cooling oil

1

Hose coupling (air cooler venting)

2

Pressure gauge

3

Hose coupling (oil separator tank venting)

4

Oil filler port with plug

5

Cooling oil level indicator

6

Male hose fitting

7

Shut-off valve

A

Shut-off valve open

B

Shut-off valve closed

8

Maintenance hose

1. Vent the machine as described in section 10.15.1.

2. Fill with cooling oil and test run as described in section 10.15.2.

10.15.1 Venting the machine (de-pressurizing)

Venting takes place in three stages:

■ Isolate the compressor from the air system.

■ Vent the oil separator tank.

■ Manually vent the air cooler.

10 Maintenance

10.15 Replenishing the cooling oil

9_5875 33 USE

Operator Manual Screw Compressor

SM Tri-Voltage, SIGMA CONTROL 2

67