The life of the oil separator cartridge is influenced by:

■ contamination in the air drawn into the compressor,

■ Adherence to the changing intervals for:

─ Cooling oil

─ Oil filter

─ Air filter

The machine must be isolated from the compressed air network and completely vented be‐

fore undertaking any work on the pressure system.

Material Spares

Cleaning cloth

Precondition The supply disconnecting device is switched off.

The disconnecting device is locked in the off position.

A check has been made that no voltage is present.

The machine is fully vented,

the pressure gauge on the oil separator tank reads 0 psi.

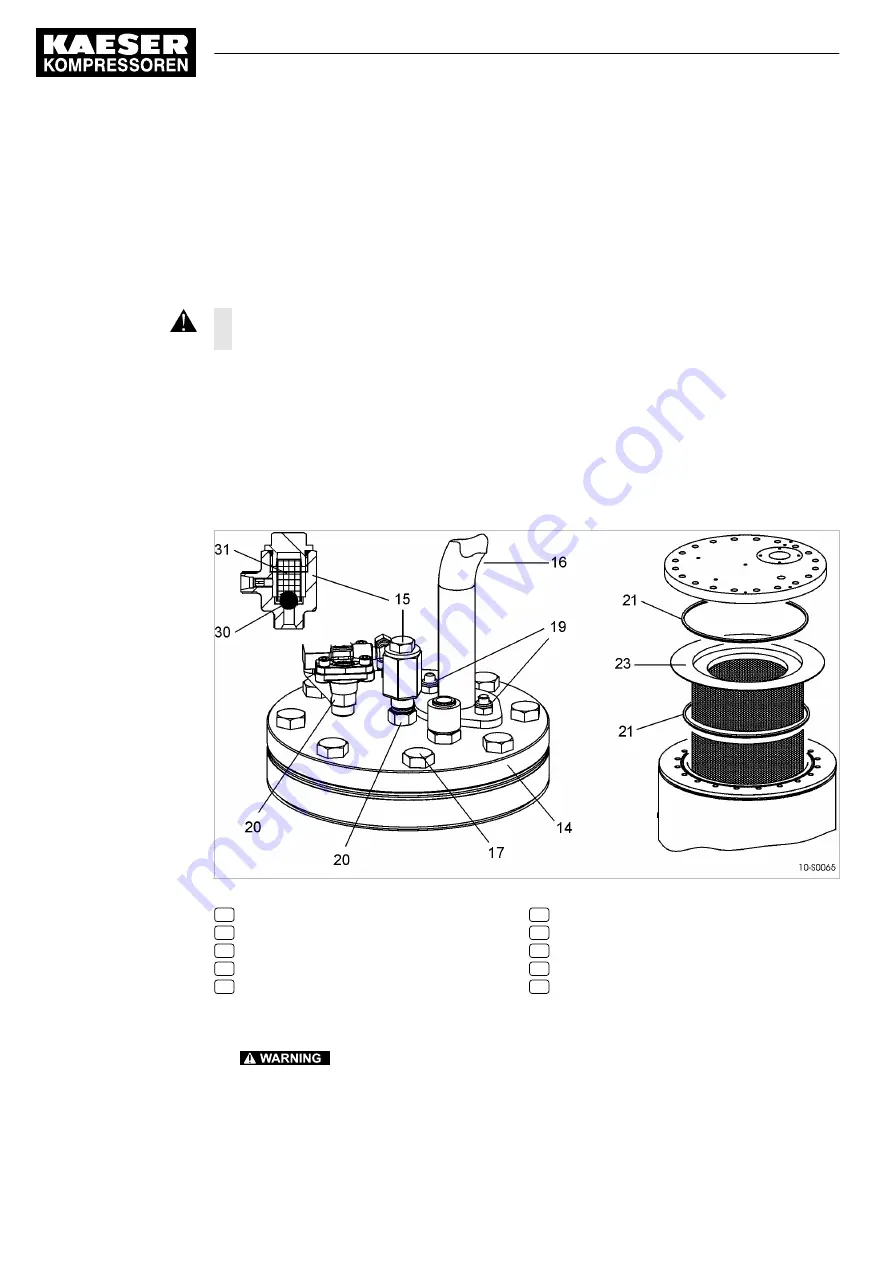

Fig. 33 Changing the oil separator cartridge

14

Cover

15

Dirt trap

16

Air pipe

17

Retaining screw

19

Self-locking nut

20

Screw connection

21

seal

23

Oil separator cartridge

30

Ball (functioning as a check valve)

31

Strainer

Changing the oil separator cartridge

1.

Compressed air!

Compressed air and pressurized devices can cause serious injury or death if the contained en‐

ergy is suddenly released.

➤ Vent all pressurized components and chambers completely.

10 Maintenance

10.18 Changing the oil separator cartridge

74

Operator Manual Screw Compressor

SM Tri-Voltage, SIGMA CONTROL 2

9_5875 33 USE