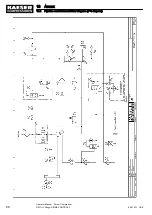

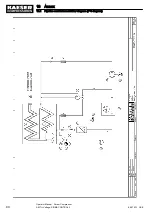

2. Unscrew the fitting

20

and carefully put the parts to one side, then pull out the copper pipe at

item

15

.

3. Unscrew the nut

19

and turn the air pipe

16

to one side.

4. Remove the cover fixing screws

17

and carefully remove the cover

14

.

5. Take out the old oil separator cartridge

23

together with the gaskets

21

and dispose of ac‐

cording to environmental protection regulations.

6. Clean all sealing faces.

7. Insert the new oil separator cartridge with gaskets and refix the cover.

8. Renew the O-ring and strainer in the dirt trap

15

.

➤ Make sure the ball

30

is properly seated.

The ball prevents cooling oil being pressed into the separator cartridge.

9. Attach the air pipe to the cover

14

with a new, self-locking nut.

10. Replace and tighten all fittings.

➤ Dispose of parts and materials contaminated with oil in accordance with environmental

protection regulations.

Start the machine and carry out a trial run

1. Close all access doors, replace and secure all removable panels.

2. Open the user's shut-off valve between the machine and the air distribution network.

3. Switch on the power supply and reset the maintenance interval counter.

4. After approx. 10 minutes of operation: Switch off the machine and check visually for leaks.

10 Maintenance

10.18 Changing the oil separator cartridge

9_5875 33 USE

Operator Manual Screw Compressor

SM Tri-Voltage, SIGMA CONTROL 2

75