Safety

2 --- 8

-

Do not allow open flame and flying sparks at the installation site.

-

Take necessary precaution when welding on or near the compressor package to en-

sure that sparks or high temperatures cannot cause fire or explosion.

-

Ensure that the compressor package is supplied only with clean uncontaminated air.

-

Do not allow the maximum ambient temperature to be exceeded (see chapter 1.6),

unless special measures have been agreed upon between the manufacturer and the

customer.

-

Perform oil changes according to the service manual or at least once annually (see

chapter 9.12).

-

Do not mix cooling oils of different types.

-

Maintain and monitor the operating temperature according to the manufacturer’s

specifications to avoid build ---up of condensate or varnish in the oil circuit (see

chapter 1.1).

-

Use only cooling oils recommended by the manufacturer (see chapter 1.8).

-

If maintenance work is carried out on any part of the oil circulation system, top off the

oil in the oil separator tank to the maximum level, run the compressor and keep it

under constant observation for a short period. Check the oil level again and top off

with oil to replace the oil taken up by the piping and the cooling system.

-

Operation of compressor package is not recommended if the differential pressure

across the separator cartridge is greater than 14.5 psi. Check periodically.

2.3

Electrical Power Supply

The main power supply and overcurrent protection must be installed

by a qualified electrician in accordance with NEC, OSHA and any appli-

cable local codes.

Compressor packages must be installed with a lockable main discon-

nect and fuses or other short-- circuit and ground fault protection de-

vice.

For fuse and wire recommendations, see chapter 1.4

Please note that the conductors, fuses and procedure are KAESER’s

recommendations. These recommendations do not supersede other

applicable codes.

2.4

Spare Parts

Safe and reliable operation of the compressor package is guaranteed only with KAESER

original spare parts and KAESER SIGMA cooling oil.

2.5

Compressed Air System

If a compressed air system is extended or changed, verify that the blowoff pressure and

capacities of the safety relief valves on the air receiver tanks and in the system match the

rating of all the compressor packages installed.

Attention!

Summary of Contents for SM 8

Page 9: ...Technical Specification 1 6...

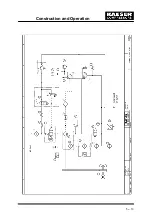

Page 16: ...Construction and Operation 5 13...

Page 17: ...Construction and Operation 5 14...

Page 54: ...Appendix 11 51 11 Appendix 11 1 Wiring Diagram...

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 74: ...SM 8 SM 11 A 08 B 07 C 14 D 11...

Page 76: ......

Page 78: ......

Page 80: ......

Page 82: ......