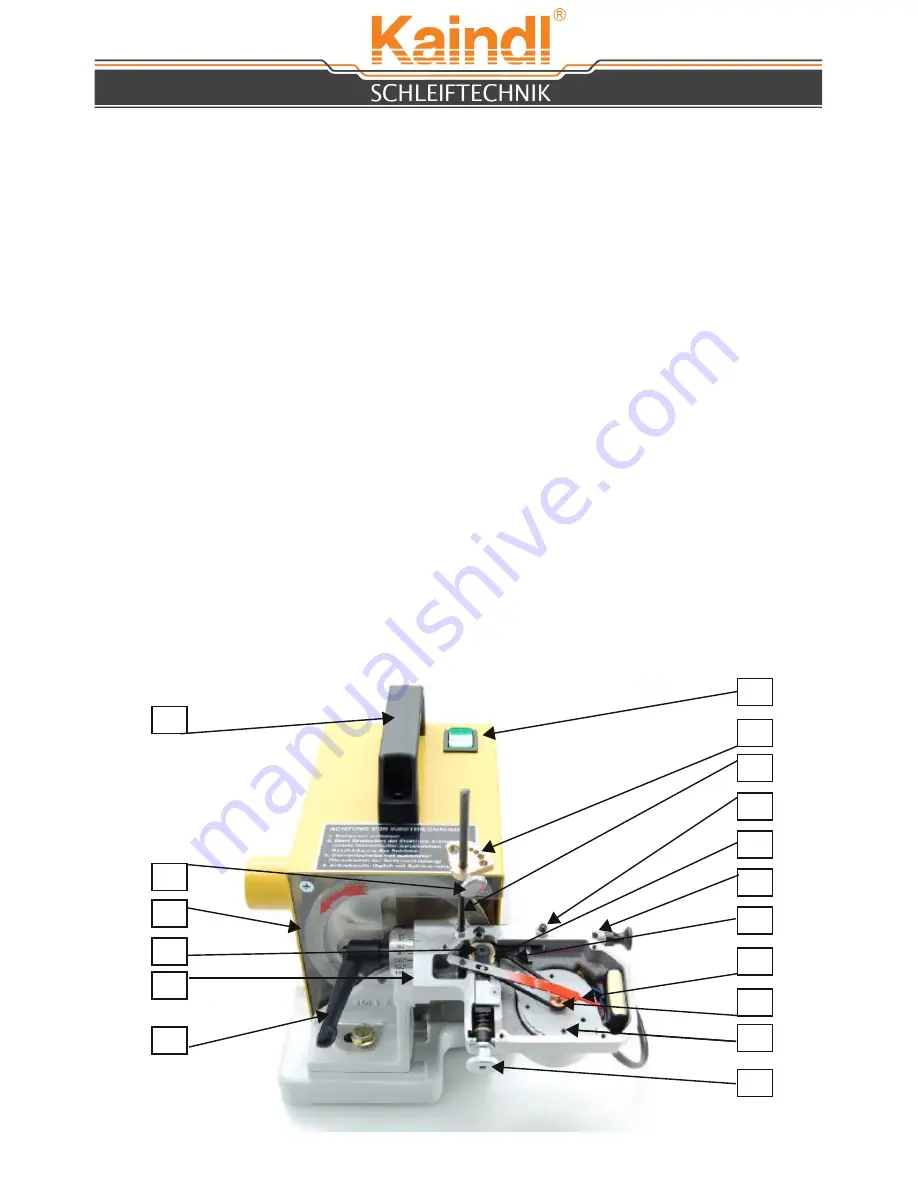

12.

SPARE

PART

LIST

Item Item No.

Description

1

10745

Diamond grinding wheel D 107 (standard)

incl. adaptor

10744

Diamond grinding wheel D 76 (medium)

incl. adaptor

10743

Diamond grinding wheel D46 (fine)

incl. adaptor

2

10760

Knurled screw M4 x 12 mm for guidance bloc

3

10758

Guidance bar M5 x 140 mm for electrode

4

16592

Guidance block complete with knurled screw M4 x 12 mm

5

10757

Knurled nut M5 x 20 mm for drive control

6

10762

Locking screw M5 for adjustment slide

7

10765

Casing of electrode drive, painted

8

10764

Motor switch, green lighted, 2 poles 230 V

9

10761

Adjustment slide 1,0 / 1,6 / 2,0 / 2,4 / 3,2 / 4,0 mm

10

10755

Drive belt 3 x 40 mm

11

10750

Synchronous motor for electrode drive 230 Volt / 50 Hz

12

10752

Pulley Ø 19 mm with ball bearing for drive unit

13

10751

Pulley Ø 12 mm for synchronous motor

14

10756

Fork head complete with pulley 19 mm and ball bearing

15

10763

Locking lever M8 for angle adjustment

10748

Grinding motor, 230 V /50 Hz; 0,05 KW; 2720 Rpm

16

Adjustment pointer for electrode diameter

17

16739

Carrying handle

10

8

4

3

6

12

99

10

16

13

11

5

17

2

1

14

7

15