7.

START

UP

AND

OPERATION

7

1.

Connect the dust exhaust of industrial vacuum cleaner with

Filter type M

to the pipe (7)

2.

Degrease the electrodes before grinding, best with spirit or similar.

3.

Adjust the top angle after opening the clamping lever (5), the number on the scale

corresponds to the top angle of the finished electrode

4.

Switch on the dust exhaust

5.

Select the diameter of the electrode with the adjustment slide (3)

6.

Turn on the machine with the main switch (1)

7.

Adjust the drive control with knob number (4) to the

requested diameter (see display)

8.

Tuck the electrode through the electrode guide with the

selected diameter of boring

9.

Turn the drive control (4) anticlockwise until the

electrode turns constantly

10. Finish the grinding operations, tear back the drive control (4)

and withdraw the electrode simultaneously

11. Switch of the machine with the main switch (1)

12. Switch off the dust exhaust

ATTENTION! By using the bushes (special accessory) let project the electrodes around

10 mm !

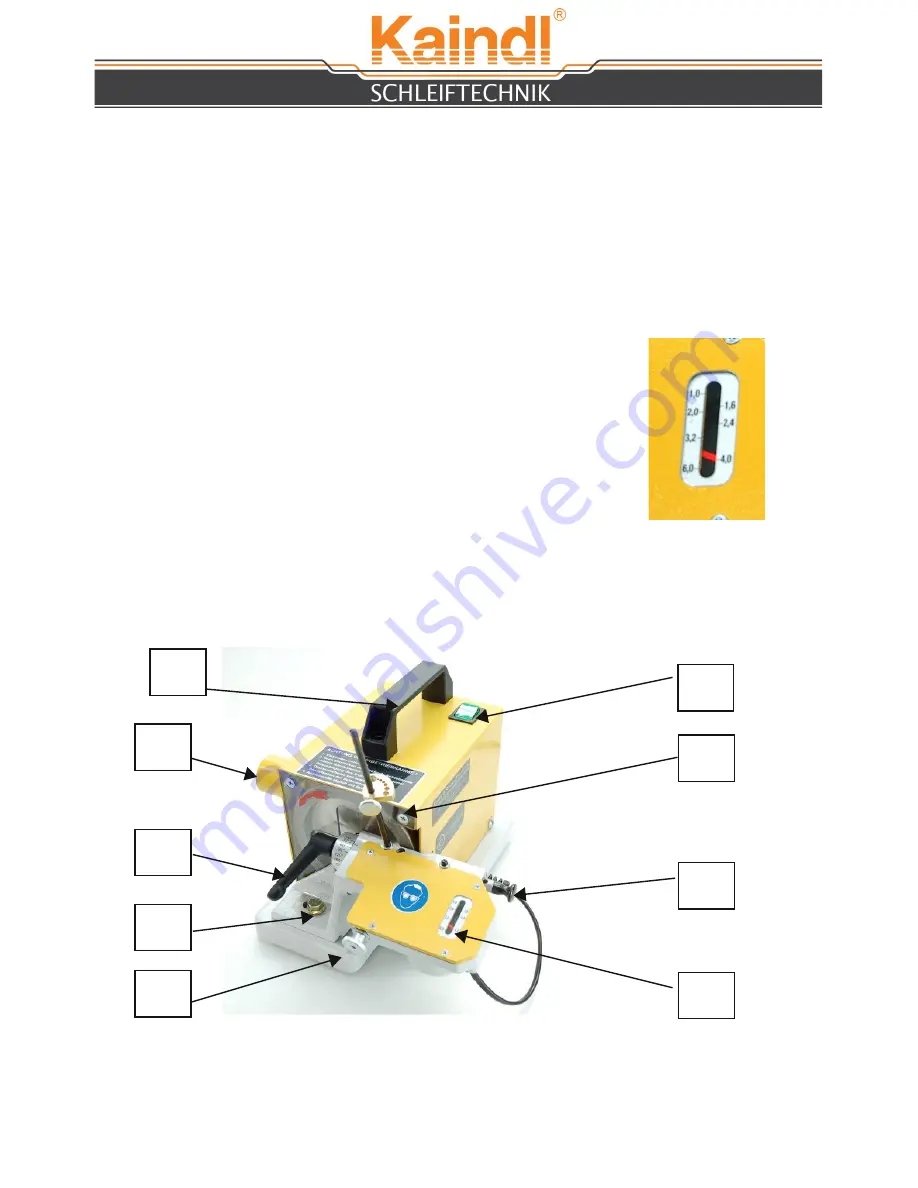

(1)

Main switch ON/OFF

(5)

Top angle adjustment

(2)

Guide for electrodes

(6)

Horizontal adjustment

(3)

Adjustment slide for electrodes

(7)

Connection pipe for dust exhaust

(4)

Drive control

(8)

Display: diameter of electrode

(9)

Carrying handle

1

2

3

8

7

5

6

4

9