Transformer/Humidity Sensor Unit

Siting the Ventilator

Page

2

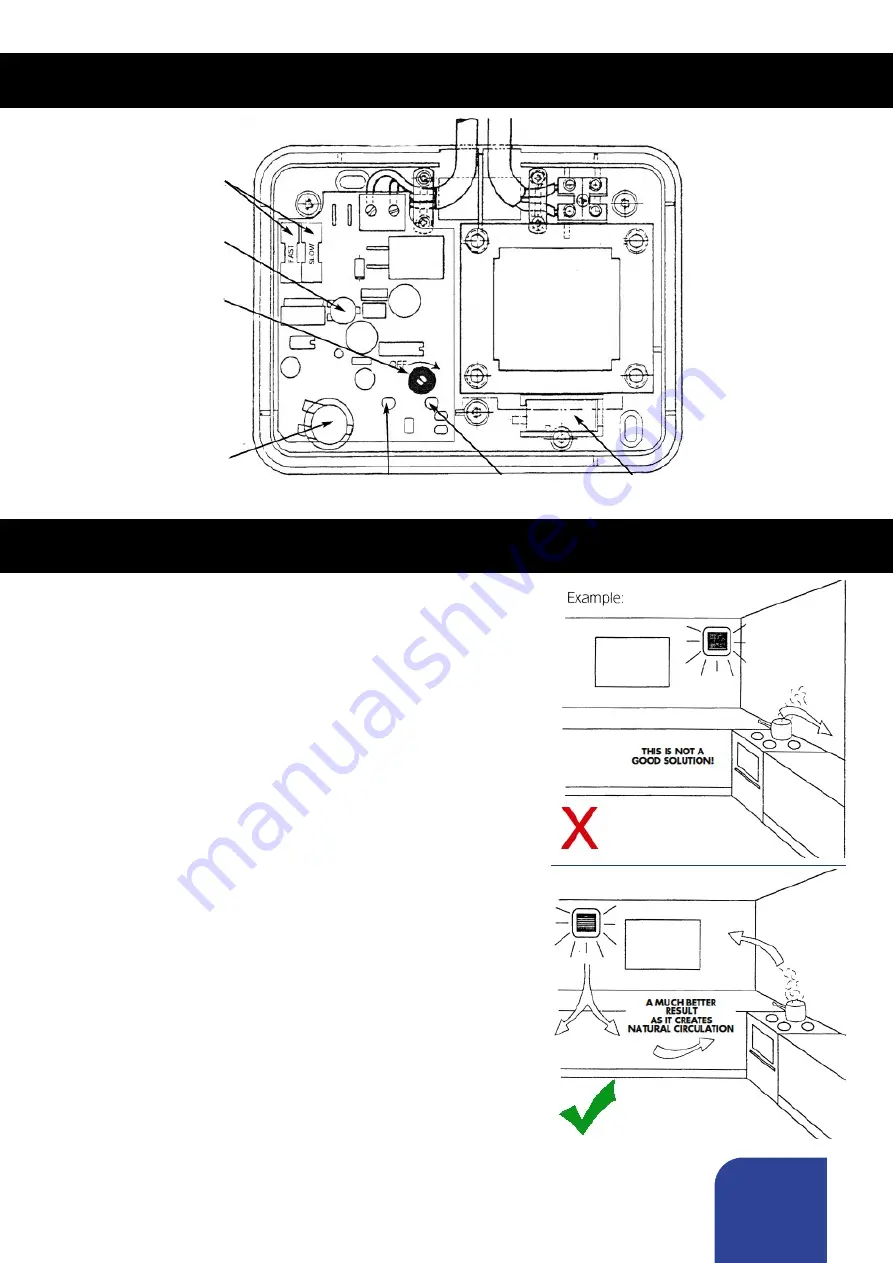

Survey the property carefully and identify the best site

for the ventilator. Condensation problems, dampness

and mould growth are stimulated by high levels of

humidity, the source of which can be the bath / shower

room, laundry room, kitchen or possibly a damp wall.

Identify an area in the room with an outside wall, which

is clear of obstruction, both inside and out - Check for

water and soil pipes, wiring and other obstructions

before finalizing your installation position.

The external cowl must be positioned a minimum of

500mm away from any gas flue to avoid back flow of

gases.

Indicate the position of the core drill hole on the inside

wall. If possible, mark its position on the outside wall

too. See if they look right.

Remember that the Heat Recovery Ventilator is unique

in that it both extracts stale, damp air and blows in

warmed fresh air. Make sure that steam from your

cooker/hob or appliance is not blown away from the fan.

a)

b)

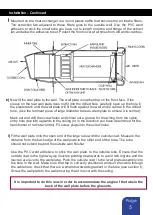

HUMIDISTAT MODEL ONLY

THUMB WHEEL HUMIDITY LEVEL

ADJUSTER (See page 1)

SELECT EITHER

SLOW OR FAST

SPEED WITH 5AMP

QUICK BLOW FUSE.

(See page 7)

FACTORY SEALED

DO NOT ADJUST

LIGHT LEVEL SENSOR

ADJUSTMENT

(See Page 8)

LOW VOLTAGE OUTPUT

MAINS INPUT

TRANSFORMER

MAINS LED

PULL CORD LED

PULL CORD SWITCH

(Manual trickle boost control)