KAIRAK

Page 5

- 5 -

IM-ES-REV 5-09-06.doc5-09-06

REFRIGERATION LINES (Remote Units)

WARNING: REFRIGERATION LINES ARE SHIPPED UNDER PRESSURE. USE CAUTION

WHEN OPENING LINES.

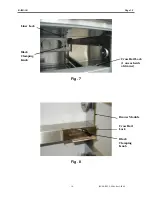

On remote units, refrigeration lines for suction and supply are located on the back of the unit

near the bottom. The suction line is marked “Suction” and is 3/8” copper tubing. The supply line

is 1/4” copper. See “Electrical Connections” section for wiring instructions.

If no holding charge is evident upon opening lines, contact Kairak Service and Parts Department

at

714-870-8661

immediately.

Cut refrigeration tubing with tube cutter (not a hacksaw) and deburr end of tube. Degrease

tubing prior to field connection. Use Silfos 5% for refrigerant line brazing. 50/50 or cold solder

is not acceptable.

For system charge, follow remote refrigeration system manufacturer’s instructions.

ELECTRICAL CONNECTIONS

Refer to the wiring diagram shipped with the unit located inside the compressor compartment or

on the back of the unit.

CORD CONNECTED UNITS (Self-Contained models)

Plug the unit into a properly sized outlet. See data plate located inside storage cabinet for

circuit sizing.

WARNING: THIS MACHINE IS PROVIDED WITH A THREE-PRONGED GROUNDING PLUG.

THE OUTLET TO WHICH THIS PLUG IS CONNECTED MUST BE PROPERLY GROUNDED.

IF THE RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN

ELECTRICIAN.

PERMANENTLY WIRED UNITS (Remote models)

A junction box located on back of the machine near bottom is provided for electrical field

connections. See wiring diagram shipped with unit on the back of the unit for electrical ratings.