PaGE 4

KrP PrEP taBlEs

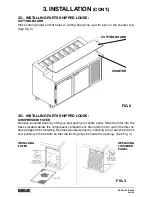

FIG. 2

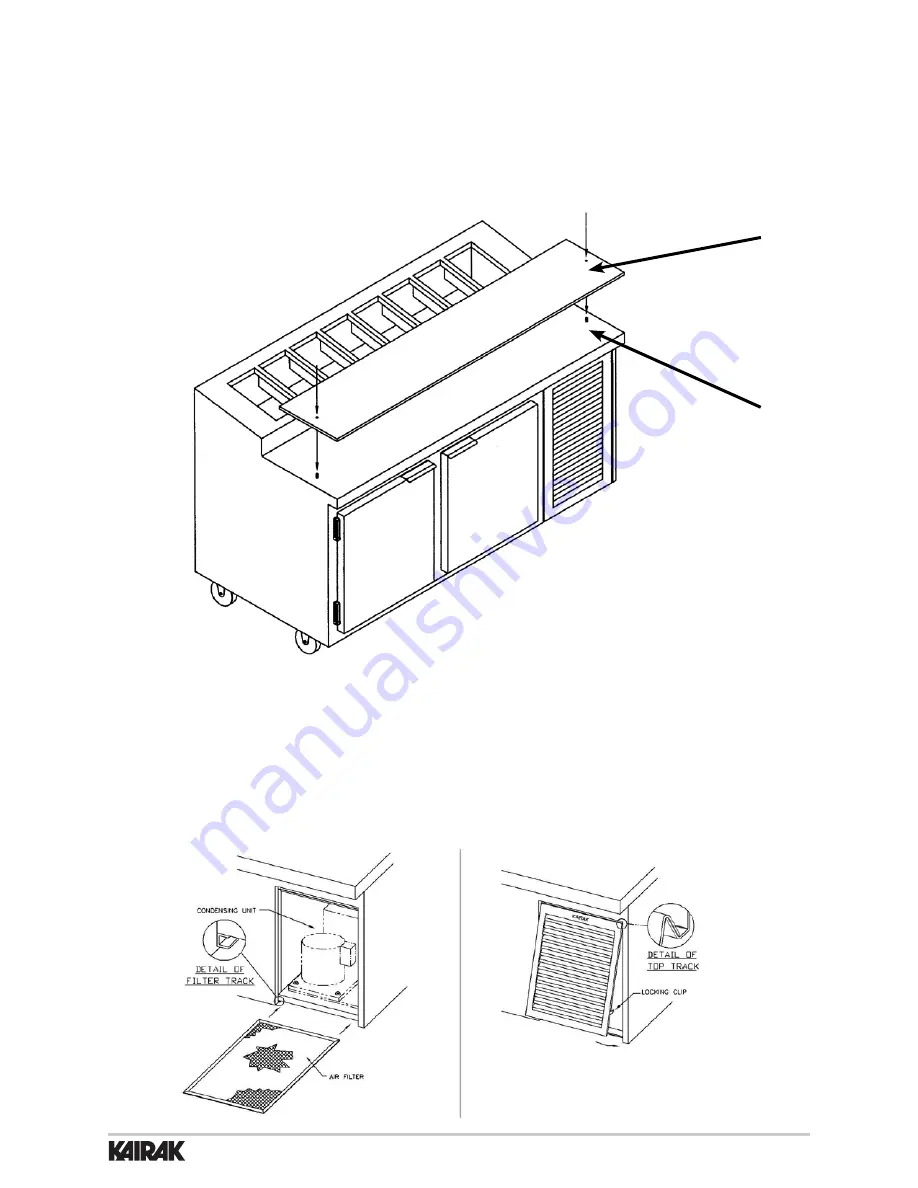

InstallInG

FIltEr

rEPlacInG

louVErED

PanEl

3c - InstallInG Parts sHIPPED loosE:

cuttInG BoarD

Place cutting board so that holes in cutting board line up with pins on the counter top.

(See Fig. 2)

cuttInG BoarD

countEr

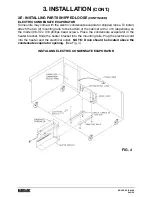

3D - InstallInG Parts sHIPPED loosE:

coMPrEssor FIltEr

Remove louvered panel by lifting up and pulling out entire panel. Slide the filter into the

tracks located below the compressor compartment. Be careful not to catch the filter on

sharp edges when installing. Replace louvered panel by installing top of panel into track

and pushing in the bottom so that the locking clips fit inside the opening. (See Fig. 3)

3. InstallatIon

(cont.)

FIG. 3

Summary of Contents for KRP

Page 23: ...NOTES...