107

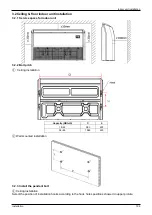

Indoor unit installation

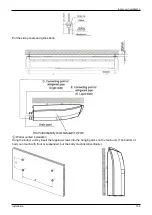

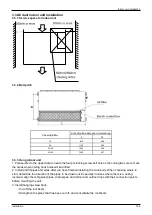

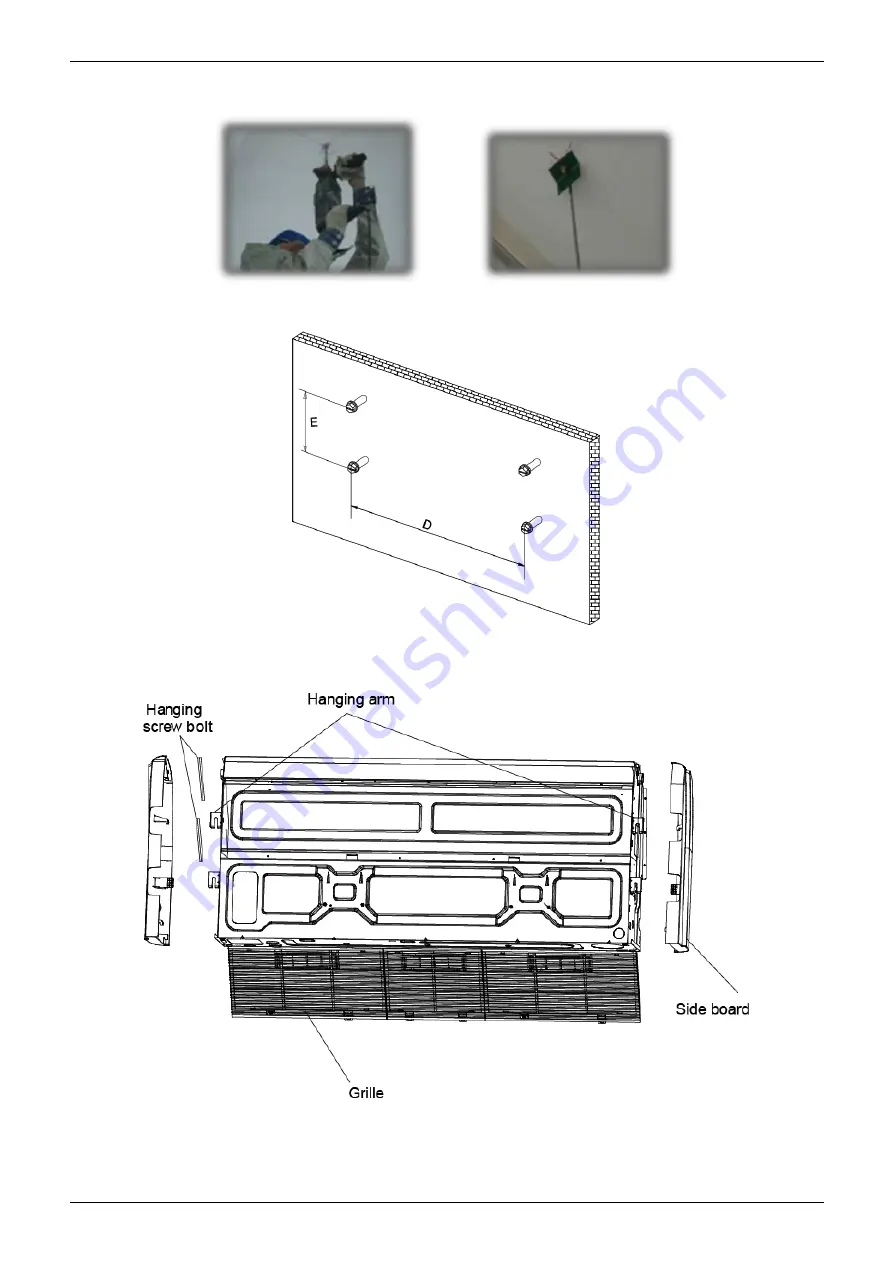

Drill four

holes of Ø12mm, 45~50mm deep at the selected positions on the ceiling. Then embed the

expansible hooks (fittings).

②

Wall-mounted installation

Install the tapping screws onto the wall.(Refer to picture below)

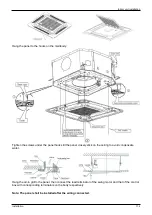

3.2.4 Install the main body

①

Ceiling installation (The only installation method for the unit with drain pump)

Remove the side board and the grille.

Locate the hanging arm on the hanging screw bolt. Prepare the mounting bolts on the unit.

Summary of Contents for KOB30U-18HFN32

Page 1: ...i KAISAI SUPER DC INVERTER SERIES Service Manual 2019 ...

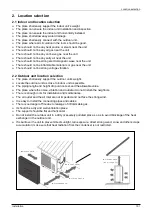

Page 12: ...Indoor Units 11 Service Space 3 Service Space 1000m m 1000mm 1000m m 1000m m ...

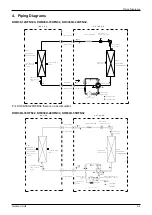

Page 15: ...Indoor Units 14 Wiring Diagrams ...

Page 20: ...Indoor Units 19 Air Velocity Distributions Reference Data 30 42K Cooling Heating ...

Page 21: ...Indoor Units 20 Air Velocity Distributions Reference Data 48 55K Cooling Heating ...

Page 26: ...Indoor Units 25 Field Wiring 10 Field Wiring KCD 24HRF32 KCD 36HRF32 ...

Page 27: ...Indoor Units 26 Field Wiring KCD 48HRF32 KCD 55HRF32 ...

Page 49: ...Indoor Units 48 Field Wiring 10 Field Wiring 18k 55k ...

Page 53: ...Indoor Units 52 Service Space 3 Service Space ...

Page 55: ...Indoor Units 54 Wiring Diagrams ...

Page 72: ...Indoor Units 71 Service Space 3 Service Space ...

Page 73: ...Indoor Units 72 Wiring Diagrams 4 Wiring Diagrams KCA3U 12HRF32X ...

Page 82: ...Outdoor Units Outdoor Units 82 10 Field Wiring KCA3U 12HRF32X ...

Page 87: ...Outdoor Units 87 Wiring Diagrams 3 Wiring Diagrams KOB30 12HFN32X ...

Page 88: ...Outdoor Units 88 Wiring Diagrams KOB30U 18HFN32 ...

Page 89: ...Outdoor Units 89 Wiring Diagrams KOCA30U 24HFN32 ...

Page 90: ...Outdoor Units 90 Wiring Diagrams ...

Page 91: ...Outdoor Units 91 Wiring Diagrams KOD30U 36HFN32 ...

Page 92: ...Outdoor Units 92 Wiring Diagrams ...

Page 93: ...Outdoor Units 93 Wiring Diagrams KOE30U 48HFN32 KOE30U 55HFN32 ...

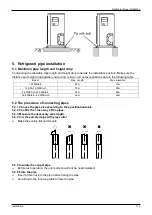

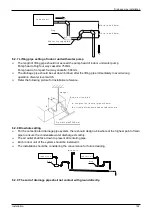

Page 118: ...Installation 119 Refrigerant pipe installation ...

Page 183: ...Controller Electrical Control System 184 ...

Page 184: ...Controller Electrical Control System 185 ...