17

8.5 Application 5

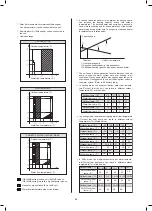

The wiring of room thermostat 5A(for fan coil units) and 5B(for floor eating loops) should follow 'method C' as described

in

9.7.6 Connection for other components/For room thermostat

, and the thermostat which connect to port 'C' (in the

outdoor unit) should be placed on the zone where floor heating loops is installed(zone B), the other one connect to port

'H' should be placed on the zone where fan coil units are installed(zone A).

NOTE

Dual setpoint function application with two room thermostat connect to the outdoor unit.

Space heating with two room thermostat application through floor heating loops and fan coil units. The floor heating loops

and fan coil units require different operating water temperatures.

The floor heating loops require a lower water temperature in heating mode compared to fan coil units. To achieve these two

set points, a mixing station is used to adapt the water temperature according to requirements of the floor heating loops. The

fan coil units are directly connected to the unit water circuit and the floor heating loops are after the mixing station. The

mixing station is controlled by the unit (or field supply, controls itself).

The operation and configuration of the field water circuit is the responsibility of the installer.

We only offer a dual set point control function. This function allows two set points to be generated. Depending on the required

water temperature (floor heating loops and/or fan coil units are required) . More details refer to

10.7 field setting /ROOM

THERMOSTAT

.

Make sure to correctly configure FOR SERVICEMAN in the user interface. Refer to

10.7 Field settings/Other heating

source

.

NOTE

Ensure that return water to the heat exchanger does not exceed 60°C. Never put the target water flow temperature set

point on the user interface above 60°C.

Make sure that the non-return valves (field supply) are correctly installed in the system.

The supplier will not be held liable for any damage resulting from failure to observe this rule.

CAUTION

During heating operation of the unit, the unit will operate to achieve the target water flow temperature set on the user

interface. When weather dependent operation is active, the water temperature is determined automatically depending on the

outdoor temperature.

During heating operation of the boiler, the boiler will operate to achieve the target water flow temperature set on the user

interface.

Never set the target water flow temperature set point on the user interface above (60°C).

2 3

6 7

8.1

8.2

8

10

9

11

11

FHL1

FHL2

FHLn

FCUn

FCU2

FCU1

17

T

T

4

5B

5A

23.1

23

23.2

24

A

B

1

1.5

1.4

1.2

1.3

1.7

1.6

1.1

18

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

2

3

Assembly unit

Assembly unit

Coding

Coding

4

6

Outdoor unit

Manometer

Pressure relief valve

Expansion vessel

Plate heat exchanger

Air purge valve

Flow switch

P_i: Circulation pump in the unit

Y-shape filter

Stop valve (field supply)

Wired controller

Drain valve (field supply)

7

8

8.1

8.2

9

10

11

17

23

23.1

FCU 1...n

Fill valve (field supply)

Balance tank (field supply)

Air purge valve

Drain valve

Expansion vessel (field supply)

P_o: Outside circulation pump (field supply)

Collector / distributor

(field supply)

FHL 1…n

5B

Room thermostat for zone 2

(field supply)

Floor heating loop (field supply)

Bypass valve (field supply)

Mixing station (field supply)

P_c: zone 2 pump (field supply)

Fan coil units (field supply)

23.2

SV3: 3-way valve (field supply)

24

Tw2: Zone 2 water flow temp. (individual purchase)

NOTE

The volume of balance tank(8) should be greater than 40L. The drain valve (6) should be installed at the lowest

positon of the system. Pump(10) and pump(23.1) should be controlled by outdoor unit and connect to corresponding

port in the outdoor unit(refer to

9.7.6 Connection for other components/For outside circulation pump P_o and

For tank loop pump P_d and mix pump P_c

).

The advantage of the dual set point control is that the heat pump will/can operate at the lowest required water flow

temperature when only floor heating is required. Higher water flow temperatures are only required in case fan coil

units are operating. This results in better heat pump performance.

Pump operation and space heating

The pump (1.7) and (10) will operate when there is request for heating from A and / or B. Pump (23.1) will operate only when

there is request for heating from B. The outdoor unit will start operating to achieve the target water flow temperature. The target

water leaving temperature depends on which room thermostat is requesting heating.

When the room temperature of both zones is above the thermostat set point, the outdoor unit and pump will stop operating.

5A

Room thermostat for zone 1

(field supply)

NOTE

Make sure to correctly configure the room thermostat installation on the user interface. Refer to "

10.7 Field

settings/ROOM THERMOSTAT

".

It is the installers’ responsibility to ensure that no unwanted situations can occur (e.g. extremely high temperature

water going towards floor heating loops, etc.)

The supplier does not offer any type of mixing station. Dual set point control only provides the possibility to use two

set points.

When only zone A requests heating, zone B will be fed with water at a temperature equal to the first set point. This

can lead to unwanted heating in zone B.

When only zone B requests heating, the mixing station will be fed with water at a temperature equal to the second

set point.Depending on the control of the mixing station, the floor heating loop can still receive water at a tempera-

ture equal to the set point of the mixing station.

Be aware that the actual water temperature through the floor heating loops depends on the control and setting of

the mixing station.

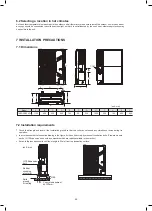

8.6 Application 6

Dual setpoint function application without room thermostat connect to the outdoor unit.

Heating is provided through floor heating loops and fan coil units. The floor heating loops and fan coil units require different

operating water temperatures.

The floor heating loops require a lower water temperature in heating mode compared to fan coil units. To achieve these two

set points, a mixing station is used to adapt the water temperature according to requirements of the floor heating loops. The

fan coil units are directly connected to the unit water circuit and the floor heating loops are after the mixing station. The

mixing station is controlled by the unit (or buy from the market, controlled by itself).

101

100

Summary of Contents for MONO KHC-22RX3

Page 1: ...INSTRUKCJA INSTALACYJNA INSTALATIONMANUAL POMPA CIEPŁA MONO MONO TYPE HEAT PUMP PL EN ...

Page 2: ......

Page 79: ...79 ...

Page 80: ......

Page 157: ...NOTE 157 ...

Page 158: ...NOTE ...

Page 159: ...16125300002403 V C ...

Page 160: ...kaisai com ...