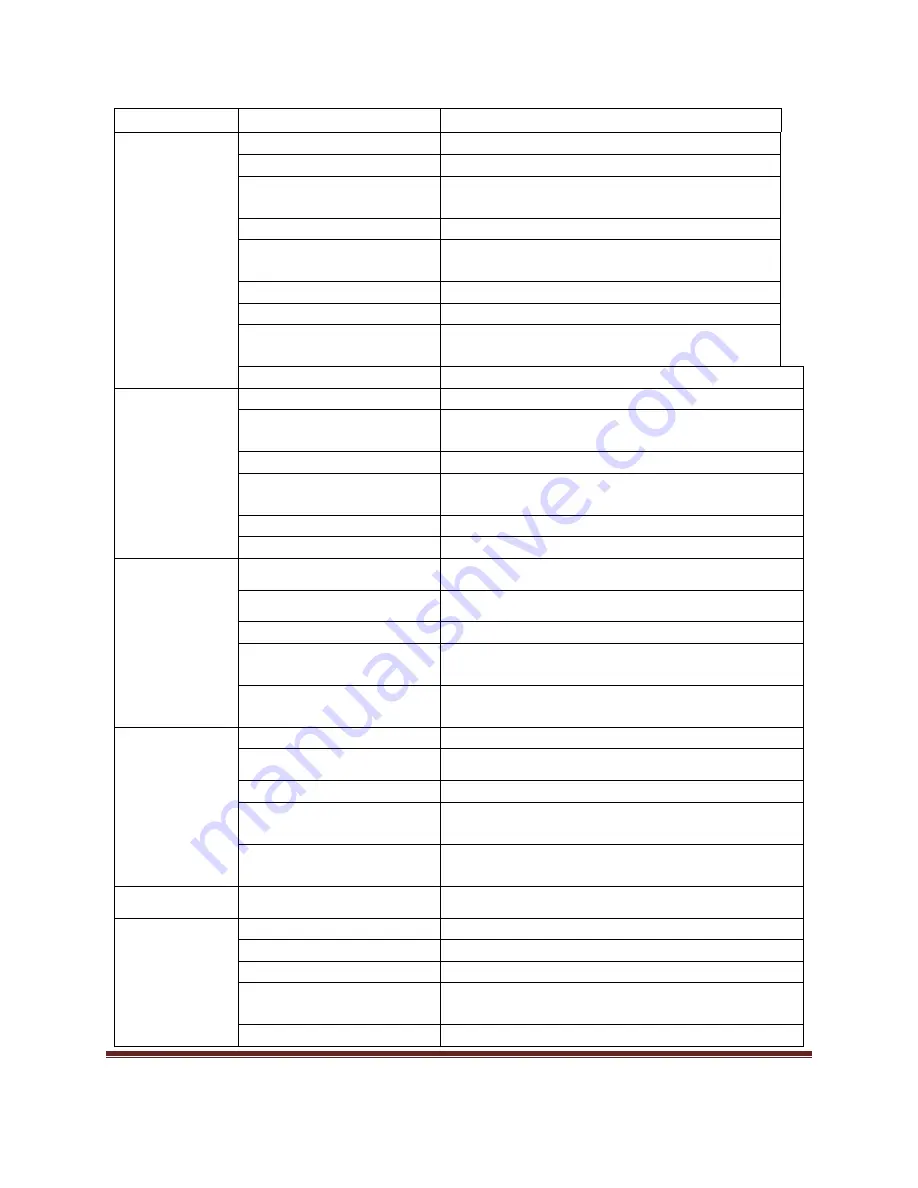

KRSL series

Page

38

to reset

Faulty air pressure sensor Repair or replace as necessary

High air

discharge

temperature

Low Fluid Level

Check oil level

Incorrect fluid brand

Check oil code number, replace as necessary

High ambient

temperature

Check air exhaust, reduce room temperature.

Plugged oil filter

Change oil filter

Plugged internal

aftercooler

Chemical cleaning for after-cooler

Dusty after-cooler fins

Chemical wash for after-cooler fins

Fan motor setting

Adjust

Temperature sensor

failure

Check and replace as necessary

Loose wire

Check and tighten

Low air

capacity

delivery

Plugged air filter

Clean air filter or replace with new element

Air Intake valve failure

Remove the intake hose and check the inlet

valve for proper operation

Separator failure

Replace separator element

Faulty indirect

proportional valve

Adjust or replace as necessary

Faulty solenoid

Repair or replace as necessary

Faulty safety valve

Repair or replace as necessary

Excessive oil

carry over in

discharge

compressed

air.

High oil level

Check oil level

Scavenging line blocked Clean or replace as necessary

Low discharge pressure

Adjust

Air/oil separator element

failure

Clean or replace as necessary

Minimum pressure valve

malfunction

Check for leaking, replace as necessary

Loading

function

Failure

Solenoid valve failure

Check and replace as necessary

Pipe leak

Check and replace as necessary

Proportional valve failure Check and replace as necessary

Air Intake valve stuck

open

Remove the intake hose and check the inlet

valve for proper operation

Minimum pressure valve

failure

Check for leaking, replace as necessary

Symptom

Possible Cause

Solution

Unloading

failure at

working

pressure,

causing safety

Pressure loading setting

Adjust as necessary

Solenoid valve failure

Check and replace as necessary

Plugged air/oil separator Check and replace as necessary

Air Intake valve stuck

open

Remove the intake hose and check the inlet

valve for proper operation

Safety valve failure

Repair or replace as necessary