Operation Manual

YP-38

Model YP-38

- 24 -

to 45

˚

. Recheck the angle before you go

on to the second bend.

Chalk-mark the ring, or set a stop, for

ease of repeating the 45

˚

bend.

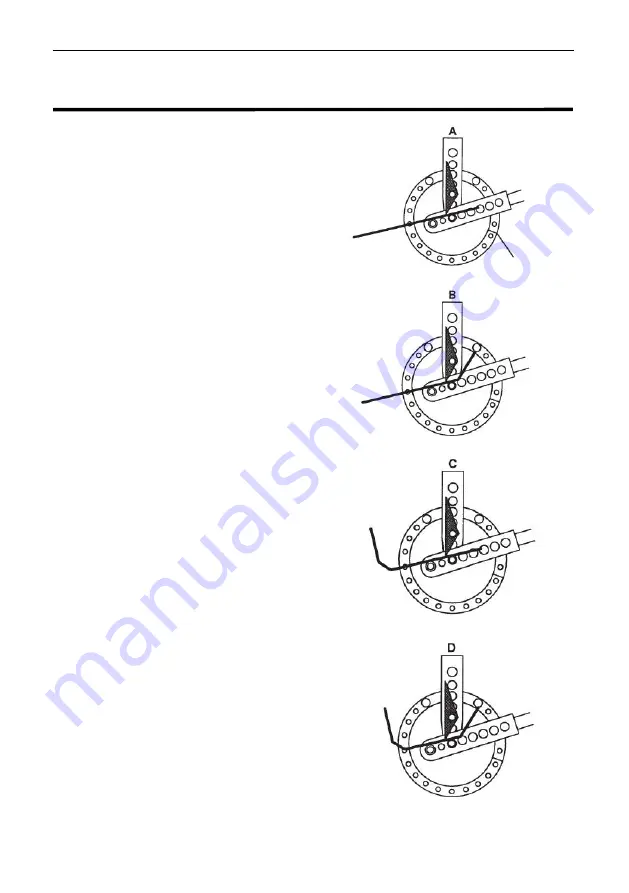

Bend No. 2

Slide the stock to the #15 chalk mark (as

in B), and bend it to 45

˚

.

Recheck the angle.

Remove the blank from the Bender.

Recheck that the bend leg is at 90

˚

to the

front of the "D".

Bend No. 3

Reverse the stock end-for-end. Slide it to

the #24 chalk mark (as in C), and bend it

to 45

˚

. Recheck the angle.

Bend No. 4

Slide the stock to the #10 chalk mark (as

in D), and bend it to 45

˚

.

Recheck the angle. Recheck that the two

legs are parallel.

To remove the part from the Bender,

remove the pin that holds the sharpangle-

bend attachment.

Finishing

Tack-weld the 6 in. piece to form the back

of the letter "D".

Grind and sand all sharp corners.

Mark