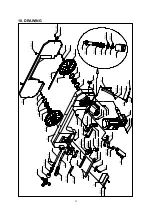

10

9. PART LIST

Item

Description

Qty

Item

Description

Qty

1

Vice handwheel

1

42

Washer

1

2

Bush

1

43

Drive flywheel

1

3

Spring 40x20.5x2

12

44

Blade

1

4

Lead screw AXK2035

1

45

Pin 10X20

1

5

Pin 8X35

1

46

Coolar 40

2

6

Tension shaft

1

47

Bearing 608-2Z

1

7

Microswitch

1

48

Coolar 25

1

8

Knob rod

1

49

Motor and gear box

1

9

Slide

1

50

Washer 10

4

10

Gib

2

51

Bolt M10X25

4

11

Bolt M8X16

6

52

Pipe fitting seat

2

12

Bolt M6X10

1

53

Bolt M4X25

2

13

Blade guide arm

1

54

Hex.cap bolt M8X10

2

14

Blade guard

1

54.1

Head screw M6X10

2

15

Washer 6

2

54.2

Back blade-guide guard

1

16

Bolt M6X10

2

55

Bolt M8X10

2

17

Clamping lever

1

56

Blade guide eccentric bush

2

18

Press block

1

57

Blade guide eccentric bush

2

19

Hex.cap bolt M6X30

2

57.1

Nut M8

1

20

Bolt M8X25

4

57.2

Bolt M8X30

1

21

Bolt M6X30

4

57.3

Nut M8

1

22

Bearing 608-2Z

4

57.4

Bolt M8x25

1

23

Blade guide block

4

58

Bolt M10X20

2

24

Bolt M8X14

4

59

Hydraulic cylinder fix seat(1)

1

25

Back adjust seat

1

60

Bush

2

26

Pipe fitting

2

61

Bolt M12X25

2

27

Hex. Socket cap screw M5X8

2

62

Hydraulic cylinder

1

28

Front blade-guide guard

1

63

Washer

1

29

Bolt M10X10

2

64

Magnetic switch

1

30

Bow

1

65

Fix seat for spring

1

31

Idle wheel

1

66

Washer 8

2

32

Bearing 627-2Z

2

67

Bolt

2

33

Bearing bushing

1

68

Nut M10

1

34

Coolar 72

1

69

Eyebolt M12X50

1

35

Washer

1

70

Bolt M10X120

1

36

Bolt M12X25

1

71

Nut M12

1

37

Blade cover

1

72

Rotor

1

38

Knob bolt M6X12

2

73

Bolt M6X20

2

39

Bolt M6X10

2

74

Bearing 32008

2

40

Washer 6

2

75

Dustproof cover

1

41

Bolt M10X25

1

76

Nut

1