11

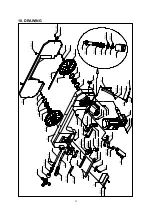

PART LIST

Item

Description

Qty

Item

Description

Qty

77

Bolt M8X10

2

116

Nut M8

1

78

Stop block

1

117

Rotating arm

1

79

Bolt M6X8

2

118

Bolt M10X30

4

80

Fix seat for rotor

1

119

Column pin 8X30

2

81

Bolt M8X25

1

120

Eyebolt M12X50

1

82

Hand wheel Φ150XΦ18

1

121

Spring

1

83

Tighten bolt M6X10

1

122

Leptospira

1

84

End housing

1

123

Control box

1

85

Lead screw AXK3047

1

124

Control box support bracket

1

86

Vice lever

1

125

Bolt M8X20

2

87

Grease cup 6

1

126

Pillow block

1

88

Tighten block

1

127

Bolt M5X16

2

89

Bolt M8X10

2

128

Vice scale

1

90

Lead screw

1

129

Pointer

1

91

Spring

1

130

Fix seat

1

92

Upper vice

1

131

Washer

4

93

Vice plate

1

132

Bolt M10X25

4

94

Bolt M8X20

2

133

Ring 3.55 x 288

1

95

Bolt M8X25

3

134

Bolt M6X10

1

96

Nut 8

3

135

Link axis

1

97

Wedge plate

1

136

Bench lever

1

98

Below vice

1

137

Nut

1

99

Support plate

1

138

Grub screw

1

100

Bolt M8X16

4

139

Handle globe M10X32

1

101

Washer 8

4

140

Shaft

1

102

Nut M8

2

141

Coolant and chip tray

1

103

Shaft stop

1

142

Roll arm assembly

1

104

Bar stop

1

143

Bolt M58X20

4

105

Knob M8X16

2

144

Washer 8

4

106

Stop block

1

145

Feed support

1

107

Nut M16

1

146

Nut

4

108

Vice plate

1

147

Bolt M6X12

2

109

Vice plate

1

148

Washer 6

2

110

Bolt M8X20

5

149

Pump

1

111

Bolt M6X20

4

150

Plate

1

112

Hydraulic cylinder fix seat(2)

1

151

Base

1

113

Fixing rod

1

152

Washer 10

4

114

Washer 10

2

153

Bolt M10X20

4

115

Bolt M8X40

1