7

correction, move it back to the lock position

.

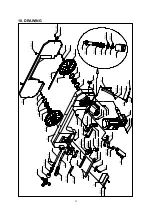

B. Clamp the material to be cut with #82 hand wheel after having positioned the clamp

near the piece to be cut. Lower #86 vice lever. Change selector switch in M

position. Turn the main switch to “1” position or “2” position you like, take hold of #7

handle located at the end of head lever and press the button. The blade will now

start turning, position the blade carefully on the piece to be cut. Then increase the

pressure in order to accelerate the cutting operation without using excessive force.

C. With selector switch in CSO position

。

Turn the main switch to the position required.

After having started the unit by pressing the START push button, the blade starts

to rotate. The down stroke of the bow can be adjusted by means of the appropriate

regulator. Position the blade carefully on the piece to be cut. Then increase the

pressure with the regulator in order to accelerate the cutting operation without

using excessive force.

D. To make a series of cuts, position the bar stop in correspondence of the size

required. Fix it into position by using #106.

E. To replace the band, carry out the same operations used to assemble the band

(chapter 5.3).

We strongly discourage the use of blades with ruined or insufficiently sharp

cutting edges

6.3 SPECIAL SAFETY CHECKS

A. Before using the machine, check carefully that the safety devices are in good

working order, that the mobile parts are not blocked, that no parts are damaged

and that all the components are installed correctly and are functioning properly.

B. Before operating the machine, make sure that the screws of the guards and other

protective devices are adequately secured, especially the screws of bow guard.

C. Check that the safety micro switches and the emergency button are functioning

correctly.

D. Make sure that the mobile guard does not leave uncovered an angle of more than

5° in order to prevent fingers from entering.

E. Pay attention to environmental conditions. Don’t expose the machine to rain, don’t

use it in damp environments, position the machine on a clean dry floor that has no

oil or grease stains.

F. Before using the machine, the operator should make sure that all tools and service

spanners used for maintenance or adjustment have been removed.

6.4 MEASURES TO PREVENT RESIDUAL RISKS

A. The removal of guards and tampering with the safety devices is strictly forbidden.

B. Gloves should always be worn.

C. Standard work clothing should be used and kept closed and should not have

flapping parts.

D. The machine should not be cleaned with liquids under pressure.

E. In the event of fire, extinguishers should not be used unless they are the powder

type. The electric power supply to the machine should always be disconnected in

these circumstances.