8

F. Do not insert foreign bodies into the motor cover and not supply the machine with

voltage by tampering with the safety micro switches or main switch.

G. Take the necessary precautions to avoid the machine being started by other

people during loading, adjustment, piece changing or cleaning.

7. MAINTENANCE AND REPAIRS

7.1 GENERAL SAFETY MEASURES

A. Lock main switch. Use the padlock in the event of machine failure or replacement

of the band. The padlock key should be entrusted to a responsible person.

B. Before carrying out any work on electrical equipment, remove the power supply

plug from the control pane (disconnect voltage).

C. Only use cables to supply power, which have a cross-section suited to the power

of the machine.

D. Authorized personnel should only carry out repairs. Only spare parts made by the

original manufacturer should be used, otherwise these could cause damage or

injury.

7.2 DESCRIPTION OF ROUTINE MAINTENANCE

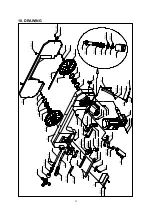

A. Adjustment of the blade guide bearings

Loosen #20 bolts, rotate #19 Hex. cap bolt, so that the blade guide bushings vertically

position the blade in axis. Tighten #20 bolts until the blade secured. The front blade

guides must be positioned the nearest possible to the piece to be cut. Check every 3

months the existing tolerance between the blade guides, making sure that it does not

exceed the blade thickness of one tenth of a millimeter, so as to avoid inexactnesses

in the cut squaring. Periodically check with mounted blade that the blade guide

bearings rotate freely.

B. Lubrication of mobile parts of piece locking vice

Remove #93 jaw, withdraw #92 vice completely by lowering #86 lever. Clean and

grease the mobile parts of #98 counter-vice and 92 vice. If the vice slid difficult, adjust

#89 bolt. Lubricate the band guide devices regularly.

C. Cleaning of the coolant tank

The coolant tank can be cleaned by simply removing #148 bolts. Empty the coolant

from the tank and collect the coolant in a container for future disposal. Clean away the

shavings and the metallic powder, taking care not to scatter this over the machine

especially around the motor and the box containing the electrical equipment. Fill the

tank with the amount and liquid stated earlier.

D. Checking of bench lever functioning

Check rotation release-locking lever is working properly regularly. In the event of the

lever not locking correctly, loosen #137 grub screw, tighten #138 nut and fasten #137

grub screw again. Make sure that with the bench lever in right position, #117 rotating

arm which supports the bow can rotate freely.