Operation Manual MUB-1

KAKA Industrial

®

— 3 —

7. Re-clamp the material. Continue the above

process until the material makes one full

revolution. A slight over bending on the final

step is required due to spring back, as shown

in Figure 3.

Figure 3

8. If you are working with heavy gauge wire,

it may be necessary to use the Sharp Angle

Plate (#15) to prevent slipping. If this becomes

necessary, it should be put on its side with the

angle portion facing up with one side of the

hole facing the vise and the other the shaft

being used, as shown in Figure 4.

Figure 4

9.If you wish to center the eye, position the

handle so that the material is on the opposite

side of the handle. This will allow the handle to

be moved counterclockwise.

10.Re-clamp the material in such a way that

the straight section is at right

angles to the vise.

11. Move the handle counterclockwise until

it meets the bender, as shown in Figure 5.

Figure 5

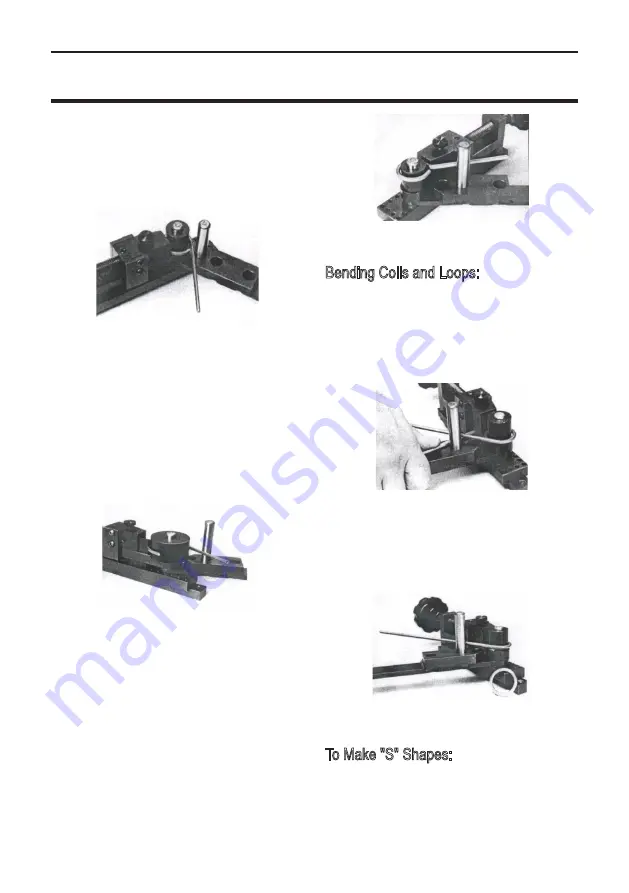

Bending Coils and Loops:

1. Repeat the top seven steps.

2. For loops and coils, you must lift the

material slightly on the third bend to allow it to

rise above the already bent material as shown

in Figure 6.

Figure 6

3. If you are doing coils, you may want to use

a spacer for the repetitive bends to ensure

that the spaces between the loops are even

and regular as shown in Figure 7.

Figure 7

To Make "S" Shapes:

1. Use the 1" Circle with the 1/2" Shaft on

the body as described in step 1 of "Eyes and

Centered Eyes".