USER MANUAL STARTER

8

TRANSLATED FROM ORIGINAL VERSION: EDITION 1

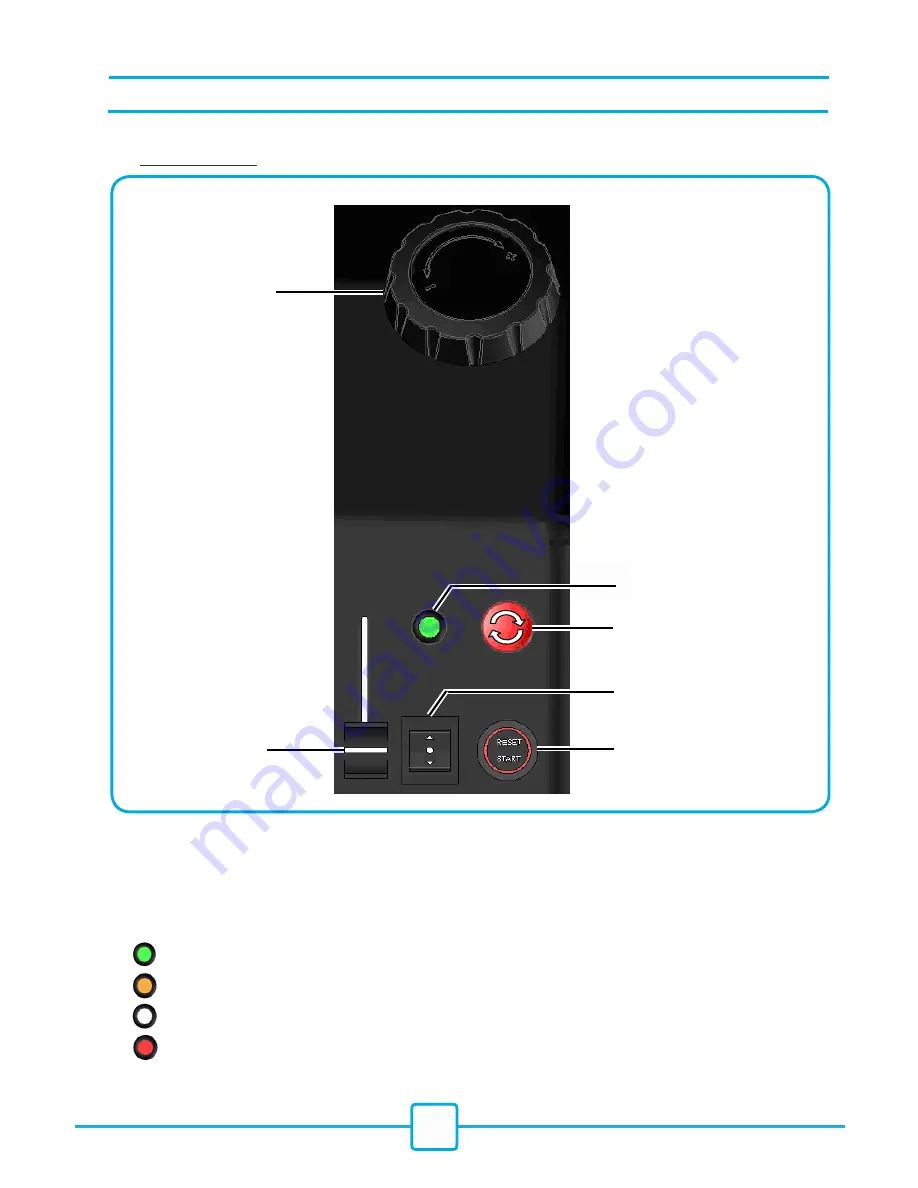

4. COMPONENTS OF THE LAMINATOR, CONTROL BOARD

4.2 Control board

A

Handle for roller elevation and pressure

adjustment of the upper roller

B

Speed adjustment

C

LED indicator for the machine working mode

-

: GREEN : Forward

-

: ORANGE : Reverse

-

: OFF : stop

-

: RED : Machine safety activated

D

Emergency switch

E

Working mode selection switch

- Forward

- Stop

- Reverse

F

Safety reset

A

D

E

B

F

C