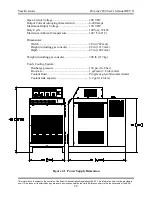

Specifications

ProLine 2200 User’s Manual REV N

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-1

Section 2 Specifications

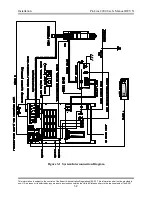

System Description

The ProLine 2200 is a microprocessor controlled, 200 amp, 100% duty cycle high current

density plasma cutting and marking system. It utilizes a precision, dual gas torch that is

capable of cutting mild steel from gauge to 2" thick and stainless steel from gauge to 1-

1/2” thick. The maximum piercing capacity is 1” thick material. The ProLine 2200 is

equipped with a manually operated gas console with pressure readouts for all gases. All

gas inlets and outlets are connected to the rear of the gas console. For excellent cut

quality on mild steel, the ProLine 2200 uses oxygen for the plasma gas and either oxygen

or air for the shielding gas. When cutting stainless steel or other non-ferrous materials,

either air or H17 (17.5% hydrogen, 32.5% argon, 50% nitrogen) is used for the plasma

gas and either air or nitrogen is used for the shielding gas. Air or nitrogen is used for the

preflow and postflow gases. When cost is of greater concern than cut quality, the

system can be configured to use clean, dry, oil-free shop air for all gas types.

The ProLine 2200 is technologically advanced to produce the highest quality cuts while

maximizing consumable life. The torch is water-cooled and consumables are machined

to exacting dimensions and checked with the latest computerized measuring systems. Six

nozzle sizes (30, 50, 70, 100, 150 and 200 amps) are available to produce excellent cut

quality throughout the cutting range.