Installation

ProLine 2200 User’s Manual REV N

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-8

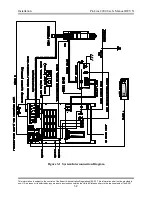

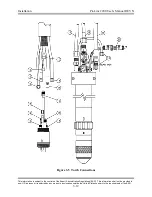

Torch Leads to RHF Console Connections

Perform the following steps to connect the torch leads to the RHF console. See Figure 3-

4 for additional information.

Note: When making hose connections, only tighten the brass

fittings enough to make water or gas seals. The fittings are

subject to damage if over tightened.

Braided Shield

•

Remove the threaded ring from the brass shield connector on the end of the

braided shield. Route the torch leads through the opening in the RHF console and

push the shield connector through the hole until it is seated against the side of the

console.

•

Slide the threaded ring over the torch leads, thread it onto the brass shield

connector, and

tighten firmly

. The shield connector should ground the braided

shield to the case of the RHF console in order to help reduce high frequency noise

emission. Using an ohmmeter, measure for zero ohms between the braided shield

and the ground stud located on the outside of the RHF console.

Torch Electrode/Coolant Supply Lead

•

Connect the Torch Electrode/Coolant Supply Lead to the brass cathode manifold.

Note that the Torch Electrode/Coolant Supply Lead has right hand threads.

Torch Coolant Return Lead

•

Connect the Torch Coolant Return Lead to the brass cathode manifold. Note that

the Torch Coolant Return Lead has left hand threads.

Torch Nozzle Lead

•

Connect Torch Nozzle Lead to the angled bracket on the red standoff. Note that

the Torch Nozzle Lead has right hand threads.

Torch CTP Sensor Lead

•

Connect the #18AWG Torch CTP Sensor Lead to the red standoff as shown.

9

10

11

12

13