Operation

ProLine 2200 User’s Manual REV N

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

4-14

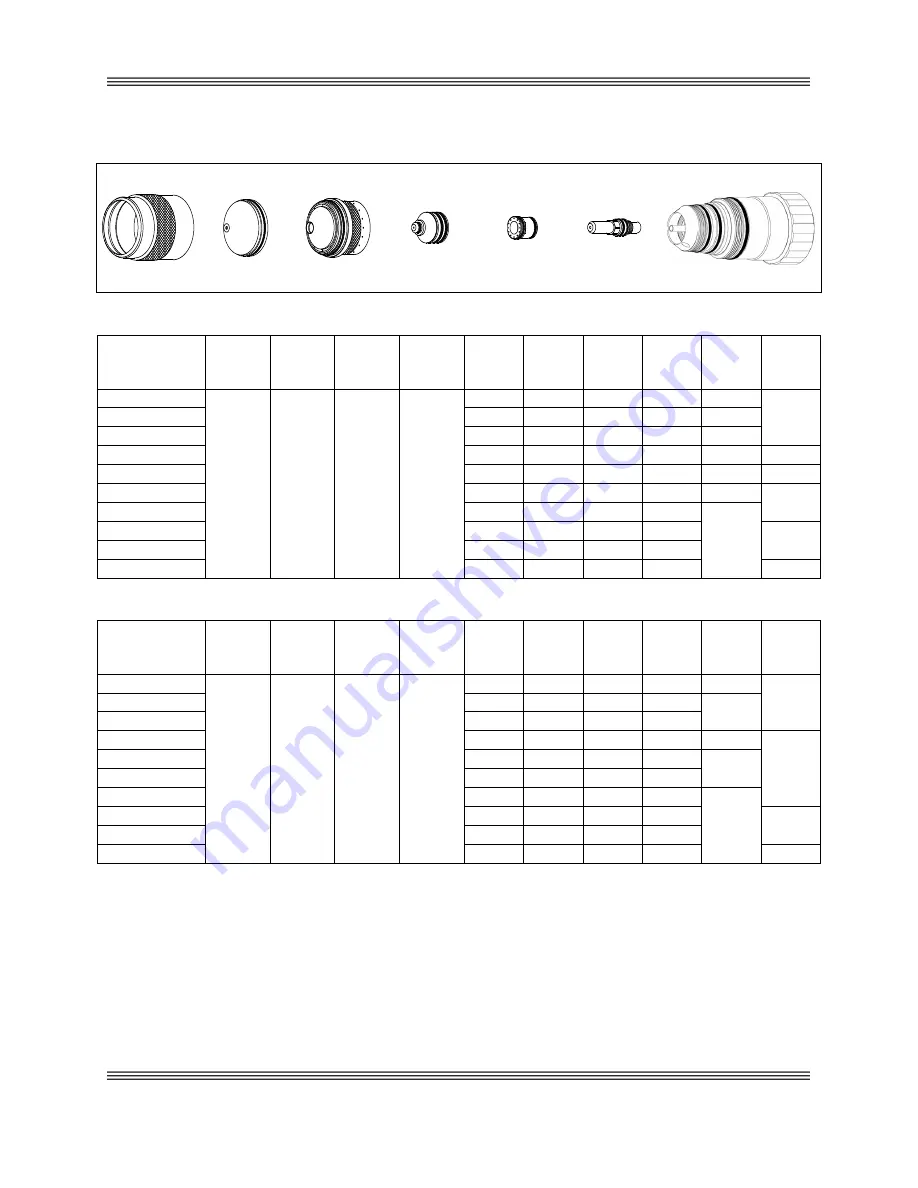

Mild Steel - 200 Amps – Oxygen Plasma / Air Shield

Copper Electrode

Shield Cap

Nozzle

Electrode

277274

277289

277291

Outer Cap

Retaining Cap

Swirl Ring

Torch Head

277154

277266

277143

279150

Imperial

Material

Thickness

Preflow

Air

Plasma

Oxygen

Shield

Air

Postflow

Air

Arc

Voltage

Travel

Speed

Cutting

Height

Pierce

Height

Pierce

Time

Kerf

Width

(in)

(psi)

(psi)

(psi)

(psi)

(volts)

(ipm)

(in)

(in)

(msec)

(in)

1/4

20

82

58

0

125

230

.040

.200

300

.150

3/8

130

140

.090

.250

400

1/2

133

120

.115

.300

500

5/8

137

100

.130

.350

600

.152

3/4

140

75

.150

.400

800

.153

1

147

50

.175

.450

1000

.155

1.25

155

25

.240

.500

1500

1.5 **

165

17

.300

.350

158

1.75 **

175

12

.350

.350

2.0 **

185

7

.500

.500

.160

Metric

Material

Thickness

Preflow

Air

Plasma

Oxygen

Shield

Air

Postflow

Air

Arc

Voltage

Travel

Speed

Cutting

Height

Pierce

Height

Pierce

Time

Kerf

Width

(mm)

(psi)

(psi)

(psi)

(psi)

(volts)

(mm/m)

(mm)

(mm)

(msec)

(mm)

6

20

82

58

0

124

6100

.8

4.9

300

3.8

10

130

3480

2.3

6.5

500

12

132

3160

2.7

7.3

16

137

2515

3.3

8.9

800

3.9

20

141

1810

3.8

10.3

1000

25

146

1310

4.3

11.3

32

155

610

6.1

12.7

1500

38 **

164

435

7.5

8.9

4.0

45 **

175

295

9.2

9.2

50 **

183

195

12.2

12.2

4.1

* Use an arc transfer height (ignition height) of .200” (4.9 mm)

** Edge start recommended

1. Revised on 01/18/2011