Maintenance and Troubleshooting

ProLine 2200 User’s Manual REV N

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

5-12

Chopper Test Procedure

WARNING: Only qualified maintenance personnel should perform the chopper test

procedure. The system utilizes potentially fatal A.C. and D.C. voltages. All

maintenance should be performed with safety in mind

Use extreme caution when working near the power conversion module (i.e., chopper).

The large electrolytic capacitors store large amounts of energy even after power has

been removed from the system. Wait at least five minutes after turning off power, and

then use a voltmeter to verify that the capacitors are fully discharged before touching

the power conversion module.

Capacitor failure can injure and/or cause property damage. If troubleshooting

requires the system to be powered with the enclosure panels removed, remain clear of

the capacitors. Failure of a capacitor can result in a sudden release of stored energy

causing rupture of the capacitor case.

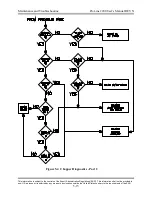

Note: A chopper troubleshooting flow chart can be found at the end of this section.

1. Turn off all power to the ProLine power supply.

2. Open the RHF console door and disconnect the black primary wires of the high

frequency transformer from the 120 VAC line filter. Close the RHF console

door to activate the door interlock switch.

3. Remove the front and left side panels from the power supply to expose the output

terminal block and the microprocessor p.c. board.

4. Remove the Electrode and Nozzle leads from the

bottom

connections of the

output terminal block (refer to Figure 3-3).

5. Apply three phase power to the unit and check the primary power on the input

terminal block TB5 (refer to Figure 3-2).

6. Depress the ON button to energize the ProLine system, and then apply a start

signal to the unit.

Note that the unit will only energize for approximately two seconds each

time a start signal is applied. When making the following readings, be sure the red DC Power

light is illuminated on the front control panel of the unit

.

After applying the start signal,

check the three phase voltage input to the chopper at the diode bridge terminals

(three right side screws on the chopper assembly) for 208 VAC. If the voltage is

not present, check for primary voltage on the main contactor CON and on the

primary side of the power transformer.

7. With a start signal applied, check for 300 VDC at the ProLine output terminal

block between Electrode and Work. If 300 VDC is present, the chopper is

working properly.

8. If 300 VDC is not present at the output terminal block, install a jumper wire

between P28-7 & P28-8 (ILK1). With a start signal applied, check for 300 VDC

at the Proline output terminal block between Electrode and Work. If 300 VDC is

present, the chopper is working properly. Check the I/O PCB (HV- Output) and

its wiring to the Microprocessor PCB.