90

GB

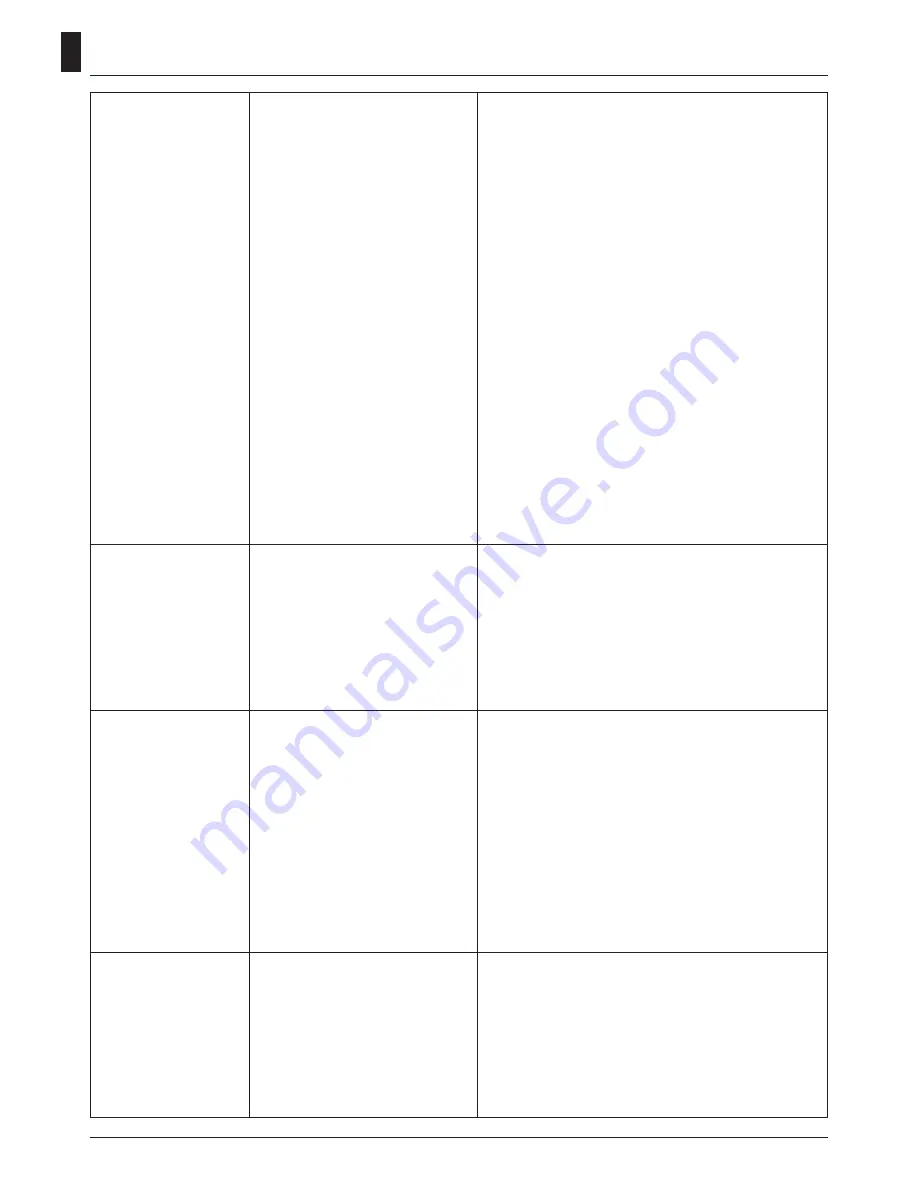

The fire goes out

or the stove stops

automatically

1. Pellet hopper empty

2. Pellets not being fed in

3. Intervention of pellet

temperature sensor

4. Door not closed properly or

gaskets worn

5. Boiler temperature is too high

6. Unsuitable pellets

7. Low pellet feed rate

8. Combustion chamber dirty

9. Smoke outlet obstructed

10. Smoke extraction motor

failed

11 Pressure switch faulty or

defective

1. Refill pellet hopper

If it is first ignition the fuel, having to go the route that

goes from the tank to the brazier, may not be able to

arrive on time and in the right amount programmed

2. If after repeated ignitions did not appear in the

flame, even with regular supply of pellets, the

problem may be related to the components of the

heater or the improper installation

3. Let the stove cool down completely, reset the

thermostat till lockout ceases, relight stove;

if problem persists, contact technical assistance

4. Close the door or

replace the gaskets with

original spare parts

5. Check for proper operation of the water pump,

if necessary, replace the component

6. Change to a type of pellet recommended by the

manufacturer

7. Have the fuel feed rate checked by technical

service

8. Clean the combustion chamber, following

instructions in the manual

9. Clean the smoke duct

10. Check the motor and replace if necessary

11. Replace the pressure

The stove runs for a

few minutes and then

goes out.

1. Lighting cycle not completed

2. Temporary failure of electricity

supply.

3. Smoke duct obstructed.

4. Temperature sensors defective

or broken.

5. Sparkplug failure.

1. Re-run lighting cycle

2. See previous instruction

3. Clean smoke duct

4. Check and replace sensors as necessary

5. Check the plug and replace if necessary

Pellet build up in

grate, door glass gets

dirty and flame is

weak

1. Insufficient combustion air

2. Pellets damp or unsuitable

3. Smoke extractor motor broken

4. Bad adjustment. Wrong ratio

between air and pellet

1. Check that the room air intake is present and free.

Check that the combustion air filter on the pipe

Ø 5 cm for air inlet is not obstructed.

Clean the grate and check that all the airways are clear.

Carry out a general cleaning of the combustion

chamber and the smoke duct.

Check the state of the door gaskets

2. Change the type of pellet

3. Check the motor and replace if necessary

4. Contact your Authorized Assistance Center

The smoke extraction

motor does not work

1. No electrical supply to

the thermostove

2. The motor is broken

3. Defective electronic board

4. Control panel broken

1. Check the supplay voltage and the protection fuse

2. Check the motor and capacitor and replace

if necessary

3. Replace electronic board

4. Replace the control panel

Summary of Contents for Alessia

Page 47: ...93 GB NOTES Cod 001143...