103

EN

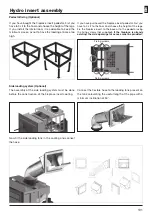

Plumbing system connection

In order to achieve the test report results, please load the performance parameters retained

by the manufacturer and the qualified technician. They will use these parameters once verified

that, during the installation, it is possibile to reproduce the laboratory conditions.

The connection of the Hydro Insert to the plumbing system must be

made ONLY by specialized personnel who are capable of carrying

out installation properly, in compliance with current standards in the

country of installation. The manufacturer will not be held responsible

for damage to persons or things in the event of failed operation if the aforementio-

ned warning is not complied with. anti-condensation valve must be installed in the

return flow. It is mandatory to install an anti-condensate valve on the return of the

system, set at 60 ° C. The valve isn’t a standard Hydro Insert component and it isn’t

delivered with the Hydro Insert.

Closed vessel system

This product has been designed and built to work with

closed vessel systems. In general, the closed vessel

system has the following expansion

as the expansion

vessel pre-loaded

. In addition to the expansion device,

the closed vessel system must be provided in accordance

with current Italian UNI 10412-2 (2009) by:

•

safety valve

•

thermostat control of the circulator

•

device alarm sounds

•

temperature Indicator

•

pressure indicator

•

audio alarm

•

automatic adjustment

•

safety thermostat with manual reset

•

circulation system

Directions for use

If the installation of the Hydro Insert provides interaction

with another existing system complete with a heater (gas

Hydro Insert, gas Hydro Insert, oil Hydro Insert, etc..)

consult qualified personnel who can then answer the

compliance of the system, as envisaged by the law in

force.

Flushing the system

In accordance with the UNI-CTI 8065 is strongly

recommended to wash the entire system before

connecting it in order to get rid of residues and

deposits.

After flushing the system to protect it against corrosion

and deposits, it is recommended the use of inhibitors.

Upstream from the Hydro Insert, always install shutters

so as to disconnect it from the plumbing system should it

be necessary to move it, or when it requires routine and/

or special maintenance. Connect the Hydro Insert using

hoses so that the Hydro Insert is not too strictly connected

to the system, and to allow slight movement.

These are as helpful as the supply and return piping

system if the heating system is on a higher floor than the

Hydro Insert.

The exhaust pipe pressure is connected temporarily to a

carafe or a funnel to avoid, in case of overpressure, that

the water gush bathrooms and the structure and the floor.

Filling the Hydro Insert funding of sanitary kit

Once all the water connections, proceed to check pressure

seal by filling the Hydro Insert. During this operation, any

air in the system is released from the

automatic vent

valve

.

C

Connection diagram for Hydro Insert

The pressure relief valve (C) must always be connected

to a water drain pipe. The tube must be capable of

withstanding high temperature and pressure.

Summary of Contents for Cloe 17B

Page 47: ...45 IT Cod 001111 NOTE...

Page 48: ...46 IT Cod 001111 NOTE...

Page 93: ...137 EN NOTES Cod 001111...

Page 94: ...138 EN NOTES Cod 001111...

Page 140: ...92 ES Cod 001111 NOTAS...