103

EN

Any inconvenience and solutions

Given that all stoves are tested in their parts handling and work and therefore are delivered in

perfect physical condition and operation, it should be remembered that the transport, unloading,

handling, misuse or poor maintenance, can be causes of drawbacks. The main problems may be

solved by reading the table below. If after doing as hereinafter described the problem is not re-

solved, contact your authorized service center.

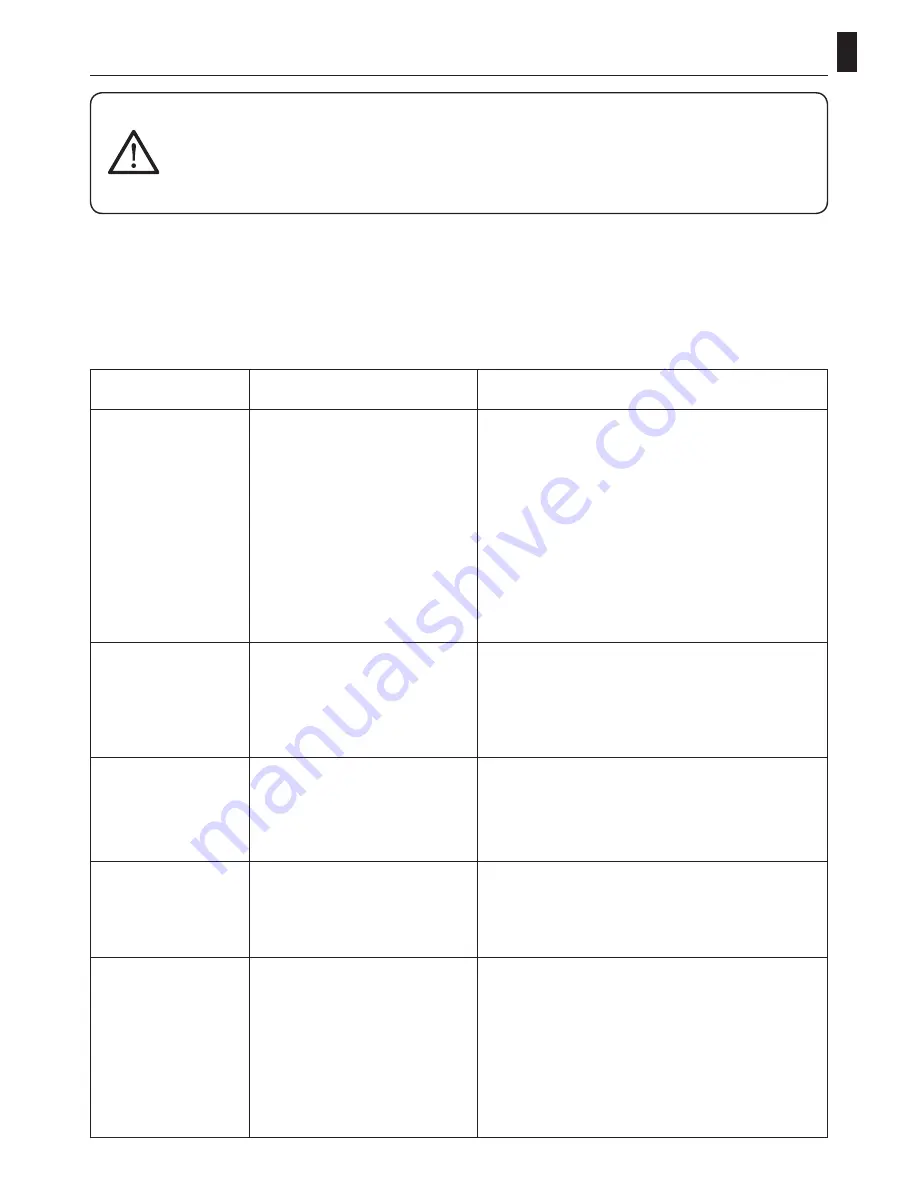

Problems and solutions

All repairs must be carried out exclusively by a specialised technician, with the

stove completely cold and the electric plug pulled out. Is prohibited from any

unauthorized modifi cation to the device and the replacement of parts with other

non-original. The operations marked in bold type must be carried out by specia-

lised personnel.

PROBLEM

POSSIBLE CAUSE

REMEDY

Display off and

buttons are not

working

1. Power failure in the net-

work

2. Switch back off

3. Display defective

4. Fault in the connection of

the display with the card

5. Fuse board interrupted

6. Card defective

1. Check that the power cord is connected

2. Use the switch back to operate it

3. Unplug the stove from the power outlet

for about one minute and then turn on. If

the problem persists, contact an authorized

service center

4. Check that the display and board are

properly connected. Contact your author-

ized service center

5. Contact an authorized service center

6. Contact an authorized service center

Remote ineffi cient

1. Too far from the stove

2. No batteries in the re-

mote

3. The remote control is

broken

1. Move closer to the stove

2. Check and change the batteries

3. Replace the remote control

Failure to ignite

the stove

1. Excessive accumulation

of ash in the grate

2. Incorrect ignition proce-

dure

1. Clean the grate

2. Repeat the ignition procedure.

If

the problem persists, contact your

authorized service center

Smoke comes

from the grill

1. Accidental electrical

blackout

1. In case of ignition phase interrupted

and momentary interruption of the fan, can

occur slight amount of smoke

Hot air fan is not

working

1. The stove has not yet

been heated

1. Wait until the conclusion of the ignition

cycle.

Arrived in temperature, the fan will start

automatically. If the problem persists,

contact your authorized service center.

Summary of Contents for Paola 13-13D

Page 38: ...108 EN NOTES Cod 001112...