46

EN

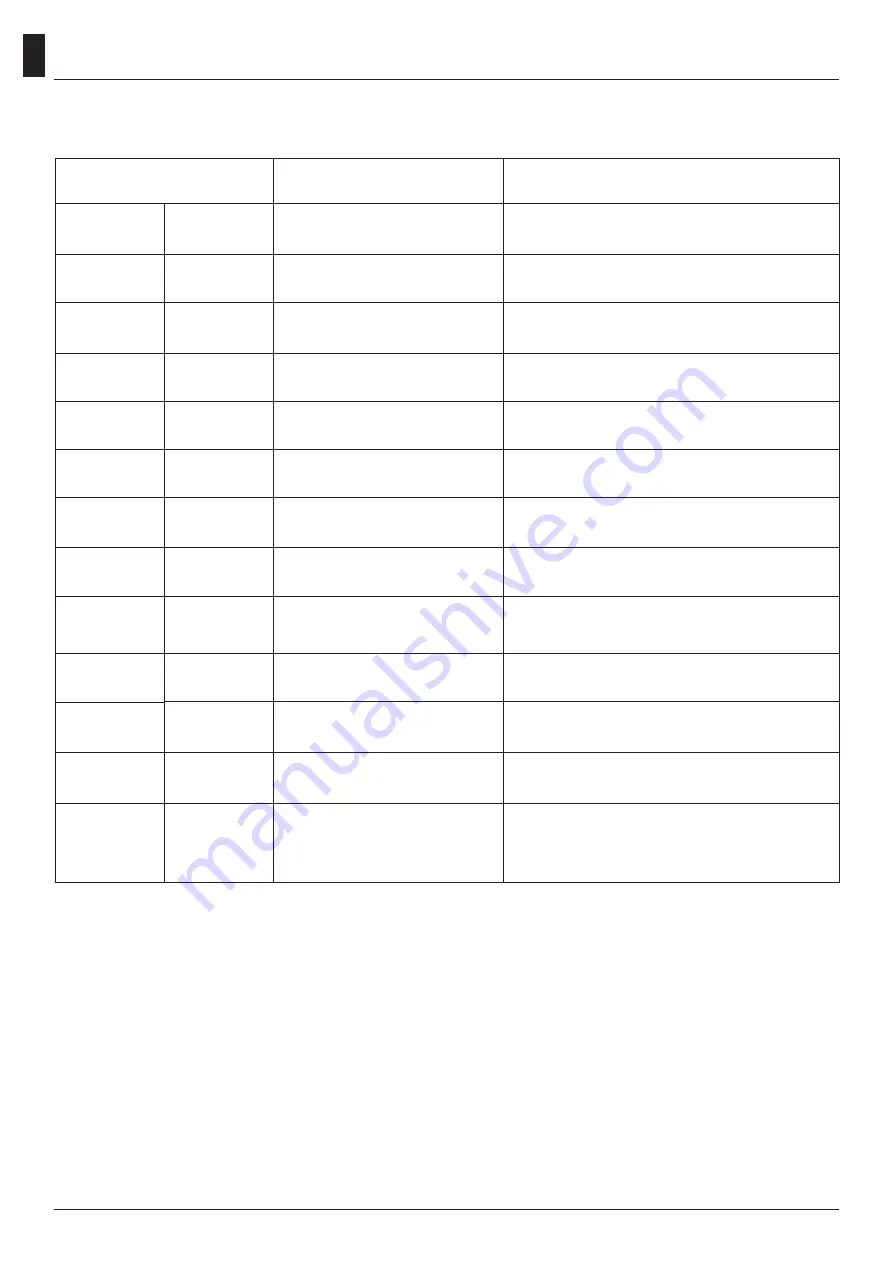

Alarm signals

In the event of a working defect, the system informs the user about the type of failure occurred.

The following table summarises the alarms, kind of problem and possible solution:

Regular checks should be carried out by the user, who should only contact the Authorized

Assistance Center if no solution is found.

Display

Kind of problem

Solution

ALAR 1

BLACK OUT

There is no power supply

As soon as the power supply is back, the Stove starts a coo-

ling cycle. After completing the cycle it starts working auto-

matically

ALAR 2

PROBE

EXHAUST

The smokes sensor is broken or not con-

nected to the pcb

Contact an Authorized Assistance Center

ALAR 3

HOT

EXHAUST

Smokes temperature too high

Switch off the Stove, allow it to cool down and perform ordi-

nary cleaning. If the problem persists, contact an Authorized

Assistance Center for cleaning the Stove and the flue

ALAR 4

FAN

FAILURE

Smokes extractor blocked or broken

Contact an Authorized Assistance Center

ALAR 5

NO

LIGHTIN

The Stove cannot start up

This is the first light-up

Fill in the tank with pellets

Start up again

ALAR 6

NO

PELLET

The pellet Stove switched off while

working

Fill in the tank with pellets

ALAR 7

SAFETY

THERMAL

The water temperature exceeds 90°C.

The circulating pump is blocked or there

is no water in the hydraulic system

Check the power supply on the pump.

Check limestone does not block the pump impeller

ALAR 8

FAILURE

DEPRESS

Obstructed flue

Clean the flue or check there are no obstructed grids near the

smokes exhaust

ALAR B

ERROR

TRIAC

COCLEA

The cochlea loads too much pellet

Contact an Authorized Assistance Center

ALAR C

PROBE

WATER

Water probe faulty

Contact an Authorized Assistance Center

ALAR D

HOT

WATER

Water temperature too high

Allow the Stove to cool down. If the problem persists, con-

tact an Authorized Assistance Center and have the hydraulic

system checked

ALAR E

PRESS

WATER

Water pressure too high

Allow the Stove to cool down. If the problem persists, con-

tact an Authorized Assistance Center and have the hydraulic

system checked

SERV

The Stove has worked for 1300 hours.

Supplementary maintenance required

Contact an Authorized Assistance Center

Summary of Contents for QUADRA 12D

Page 1: ...USER MANUAL QUADRA 12D...

Page 24: ...54 EN...

Page 33: ...63 EN NOTES Cod 001109...

Page 34: ...64 EN NOTES Cod 001109...