KPS SERIES

Technical

Documentation

M-UK-KPS--06

11/02/03 Page 109 of 138

KALTENBACH

6.2

Tools

6.2.1

Punch and Dies General Information

CAUTION

Wrong Punch Tool Settings can inflict grievous bodily harm to

persons.

The diameter of the punch hole should always be bigger than

the material thickness to be processed !

•

With all types of punch units, except the triple-unit (KPS503/ KPSA206), an

hole-in-hole can be punched, only if ¾ of the punch punches in full material.

For the triple-unit only the punch in the middle is allowed to punch hole-in-hole.

The outer most punches are not allowed to punch hole-in-hole.

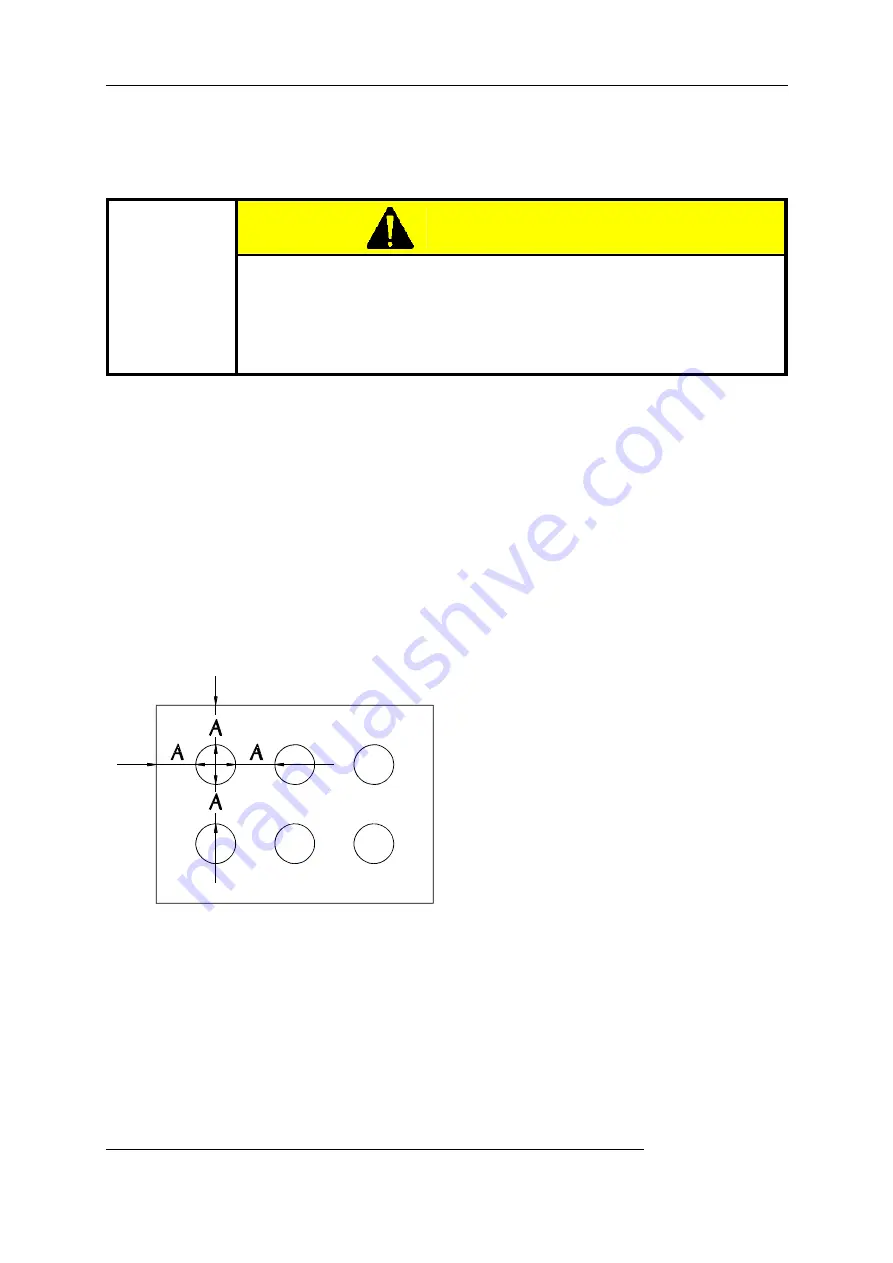

•

To reduce deforming of the material, a distance of at least 1 hole diameter of

the edge should be observed.

•

To reduce deforming of the material, a distance of at least 1 hole diameter

should be observed between each hole.

•

Use the right ‘family’ of punching tools for the vertical and flange punch. See

the supplies:

Drawing # 700055 Tool information & min punch position KPS503

•

Pay attention to using the right (special) tools for the flange punch if processing

angle steel and/or U-profile. Consult your dealer or tool supplier.

Summary of Contents for KPS Series

Page 1: ...MANUAL KPS 515 Serial No 2008 01 14564...

Page 2: ......

Page 6: ...KPS SERIES Contents M UK KPS 06 11 02 03 Page 6 of 138 KALTENBACH 7 Appendix 138...

Page 136: ......

Page 263: ......

Page 264: ......

Page 265: ......

Page 266: ......

Page 267: ......