KPS SERIES

Operation

M-UK-KPS--06

11/02/03 Page 64 of 138

KALTENBACH

-

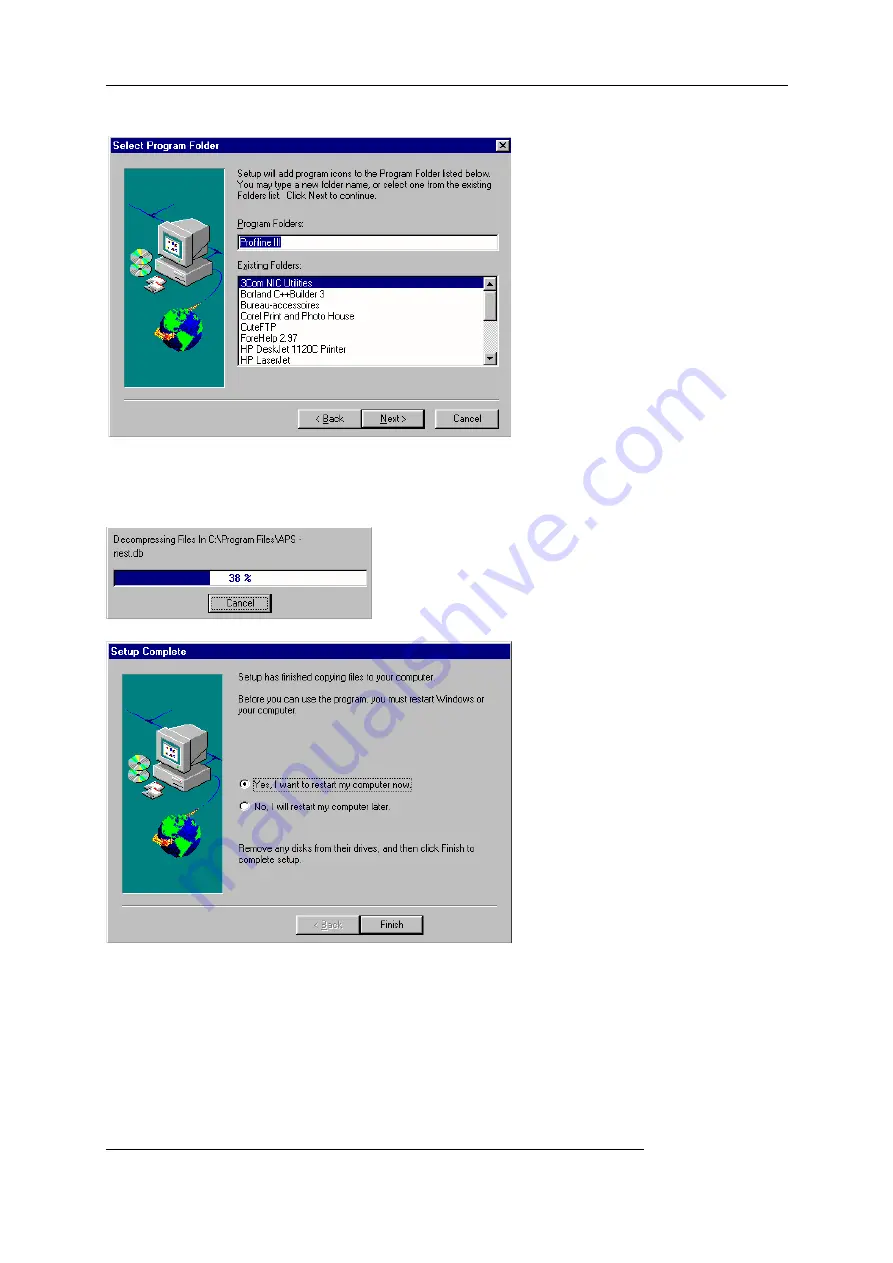

Click Next to continue to the Select Program Folder dialog box:

If you want to change the name

of the program folder, enter a

new one or select one from the

Existing Folders list.

-

Click Next.

The Copying program files screen displays indicating that program files are being

installed:

-

Click Finish.

Before you can run MULTILINE, you must restart Windows or your computer.

Summary of Contents for KPS Series

Page 1: ...MANUAL KPS 515 Serial No 2008 01 14564...

Page 2: ......

Page 6: ...KPS SERIES Contents M UK KPS 06 11 02 03 Page 6 of 138 KALTENBACH 7 Appendix 138...

Page 136: ......

Page 263: ......

Page 264: ......

Page 265: ......

Page 266: ......

Page 267: ......