- 9 -

KALVIS-100MG ... -500MG LT 2019.03.18

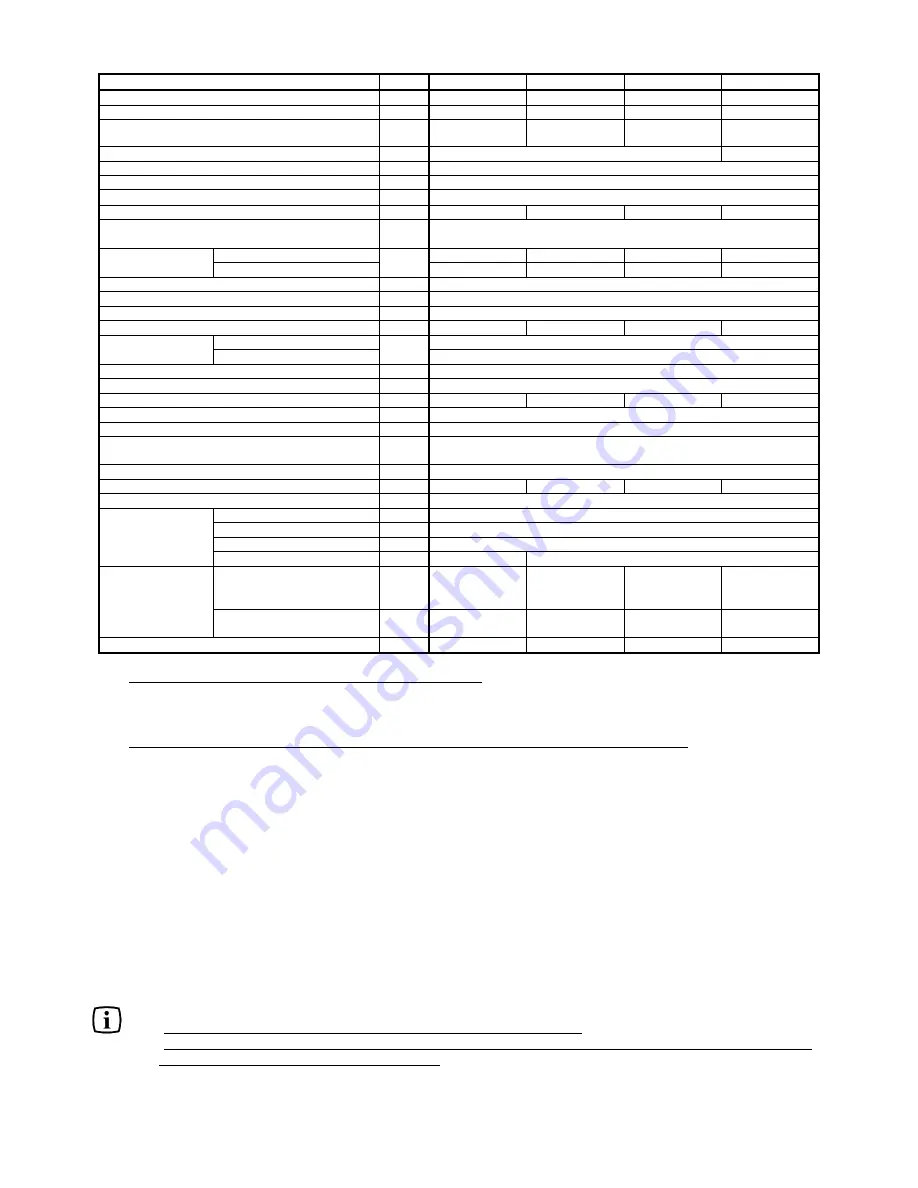

Table 1 continued

Boiler model

Kalvis-250MG

Kalvis-300MG

Kalvis-400MG

Kalvis-500MG

Nominal power (Q

N

)

kW

250

300

400

500

Minimum power (Q

min

)

kW

75

90

120

150

Burner model

UNI-MAX

250 kW

UNI-MAX

300 kW

UNI-MAX

400 kW

UNI-MAX

500 kW

Control unit

PLUM ecoMAX850P2-O

KEY RK-2006LPGP2

Fuel type

wood pellets *

1

Fuel moisture, no more than

%

10

Pellet fuel size, no more than

mm

6

– 8

Fuel consumption at nominal power

kg/hrs

65

77

114

150

Efficiency factor at Q

N

,

no less than

%

90

Heated area

B class *

2

m

2

2925..8750

3510..10500

4680..14000

5850...17500

C class *

2

1400..4175

1680..5010

2240..6680

2800...8350

Burning time without fuel refill (at Q

N

) *

3

hrs

depending on fuel volume

Boiler class acc. to LST EN 303-5

5

Service life time, no less than

years

10

Water capacity in the boiler

l

1200

1400

1400

1600

Water pressure in

the boiler

no less than

bar

(MPa)

2,5 (0,25)

no more than

4,0 (0,4)

Maximum outflowing water temperature

ºC

90

Min. return water temperature during operation

ºC

50

Hydraulic resistance (Δt=20ºC/Δt=10ºC)

mbar

0,127

0,136

0,185

0,254

Working environment temperature

ºC

3 - 30

Draught from boiler *

4

Pa

180 *

4

Exhaust smoke temperature at nominal power, up

to

ºC

130

Operation voltage

V

230 AC

Electrical power

W

585

1111

1411

1466

Electrical protection class

IP 20

Connection branch

pipe dimensions:

flue pipe (relative diameter)

mm

Ø 250

flue pipe branch pipe

mm

Ø 305

water discharge

mm (col)

25 (1")

heating system

mm (col)

50 (2")

65 (2½")

Overall

dimensions, no

more than:

height (H)

breadth (B)

length (L)

mm

mm

mm

1900 *

5

1440 *

5

3320 *

5

2170

1600

4730

2220

1760

4970

2220

1760

5270

breadth without el. panel (B1)

length without burner (L1)

mm

mm

1140 *

5

2990 *

5

1260

3110

1420

3350

1420

3650

Mass, no more than (

10%)

kg

2500 *

5

2580

3000

3420

*

1

Wood pellet quality shall be in line with DIN 51731, DIN plus standards.

*

2

Energy quantity calculated according to the requirements of STR 2.01.02:2016 Projecting and Certification of Energy Performance of

Buildings, expressed for Energy Performance of Buildings Classes B and C.

*

3

Using Ø8 wood pellets (7 % moisture and 17,5 MJ fuel heating value).

Fuel load combustion duration depends on fuel type, moisture, outside temperature, heat consumption.

*

4

Permanently constant draught from the boiler has to be ensured, so it is necessary to install smoke exhauster. For control of the smoke

exhauster, frequency converter and differential pressure sensor are recommended.

*

5

Dimensions are determined for a particular order at the time of

Peephole installed in the rear of the boiler is used to observe the combustion process visually.

For draught measurement in the boiler, branch pipes are installed on the both sides of the boiler, under

trimming covers, one branch pipe is used to pull a tube on, other end of the tube is led to the differential

pressure gauge installed in the control box (

see fig. 6

).

On the top of the rear wall of the boiler, smoke collector is installed, having three holes directed towards the

rear and the both sides. Flue pipe branch pipe is attached to one of the holes, selecting the direction, the

remaining two holes are covered with sooth removal lids.

In the boilers

Kalvis-300MG ...-500MG,

burner

UNI-MAX 500 kW

...

300 kW

is installed on rails

(

see fig. 3

).

More information about the burner and controller can be found in:

-

„

ECO-BURNER UNI-MAX 100-1000 kW Pellet Burner User Manual

“.

-

„

Burner control unit PLUM ecoMAX850P2-O (or KEY RK-2006LPGP2) for Pellet Boilers, Installation,

Service, Maintenance And Operation Manual

“.

Summary of Contents for Kalvis-100MG

Page 2: ......