LRWMANUAL 0321

KAM CONTROLS, INC.

26

K A M L R W O P E R AT I O N R E A LT E R M C O N T I N U E D

IN-LINE CALIBRATION AND VERIFICATION

1.

Launch RealTerm. Manually draw (3) samples of fluid according to API MPMS Chapter 8.1, waiting at least 15

minutes between samples.

2.

Each time a sample is drawn, note value or take a screenshot of the current % water LRW reading in the Real-

Term window.

3.

Determine water percentage in each sample using a KAM Karl Fischer Moisture Analyzer (recommended), or

other available method.

4.

Average the water content from the three manual samples.

5.

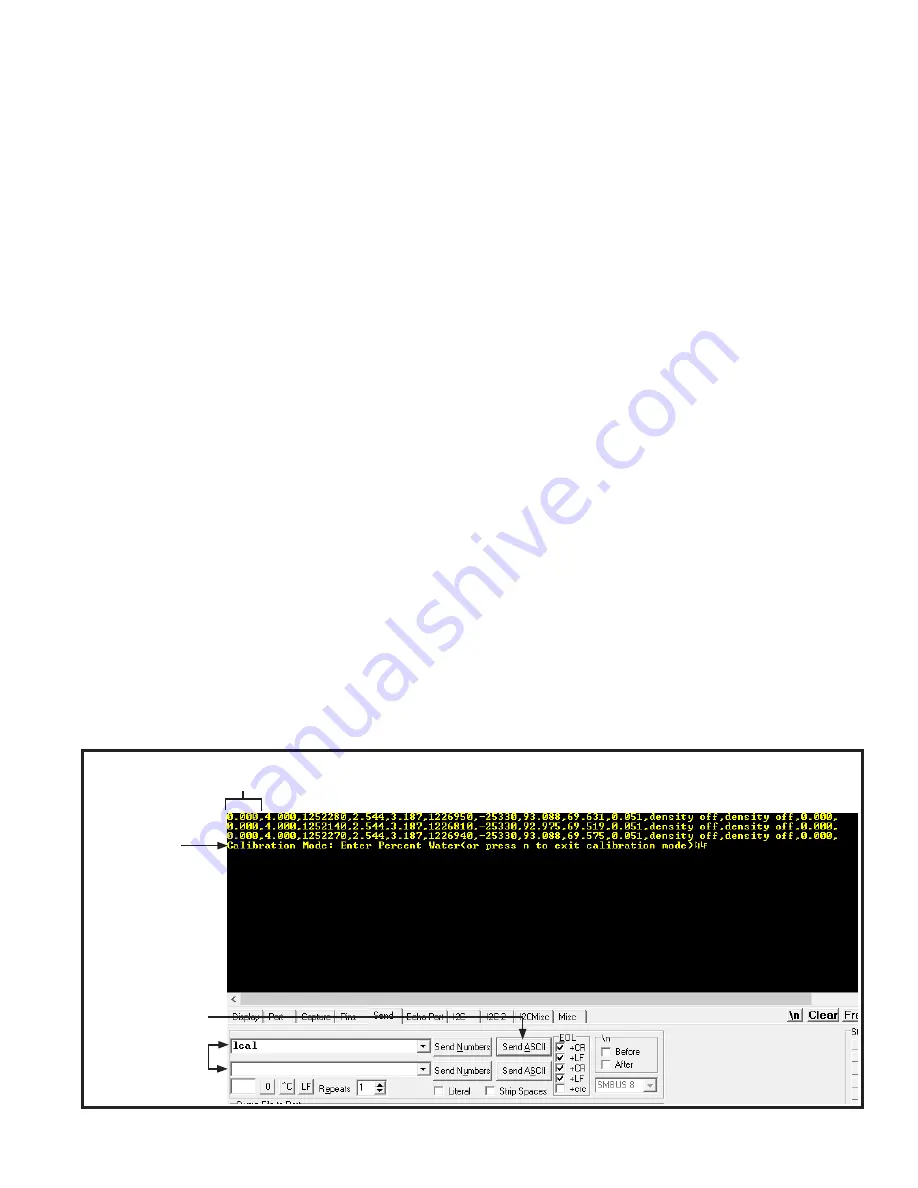

Average the water content from the three LRW readings or screenshots (first data column in RealTerm). FIG. 4-9.

6.

Take note of the current reading of the LRW in RealTerm.

7.

Calculate the difference between manual sample averages and LRW averages and add or subtract that value to

the current reading of the LRW in Realterm. This value is the calculated percent of water to be entered on

8.

Realterm to calibrate the LRW. See Calibration Example on page 27.

9.

Type "lcal" (lower case L) in either command port under the "Send" tab and click on "Send ASCII."

The "Calibration Mode" message will appear. FIG. 4-9.

PLEASE NOTE: The following calibration steps are to be conducted during initial installation with existing process

conditions; during routine verification procedures; or when LRW readings indicate a slight drift off acceptable

accuracies in continuous operation. You will need an RS232 cable (supplied) or an RS232/USB adapter (supplied), a PC

equipped with RealTerm software, and a means for manually collecting and measuring samples.

Before proceeding, install and configure RealTerm as per instructions on pages 19–21 of this manual. Ensure your

PC is connected to the OWD sensor via the supplied RS232 serial cable and USB-to-serial converter as per wiring

diagram on page 12. To access the boards,unscrew the cover from the Explosion Proof electronics enclosure,

unscrew the LCD Display plate and carefully unplug the LCD connector.

FIG. 4-9

Calibration

mode message

Command port

Send ASCII

button

% water