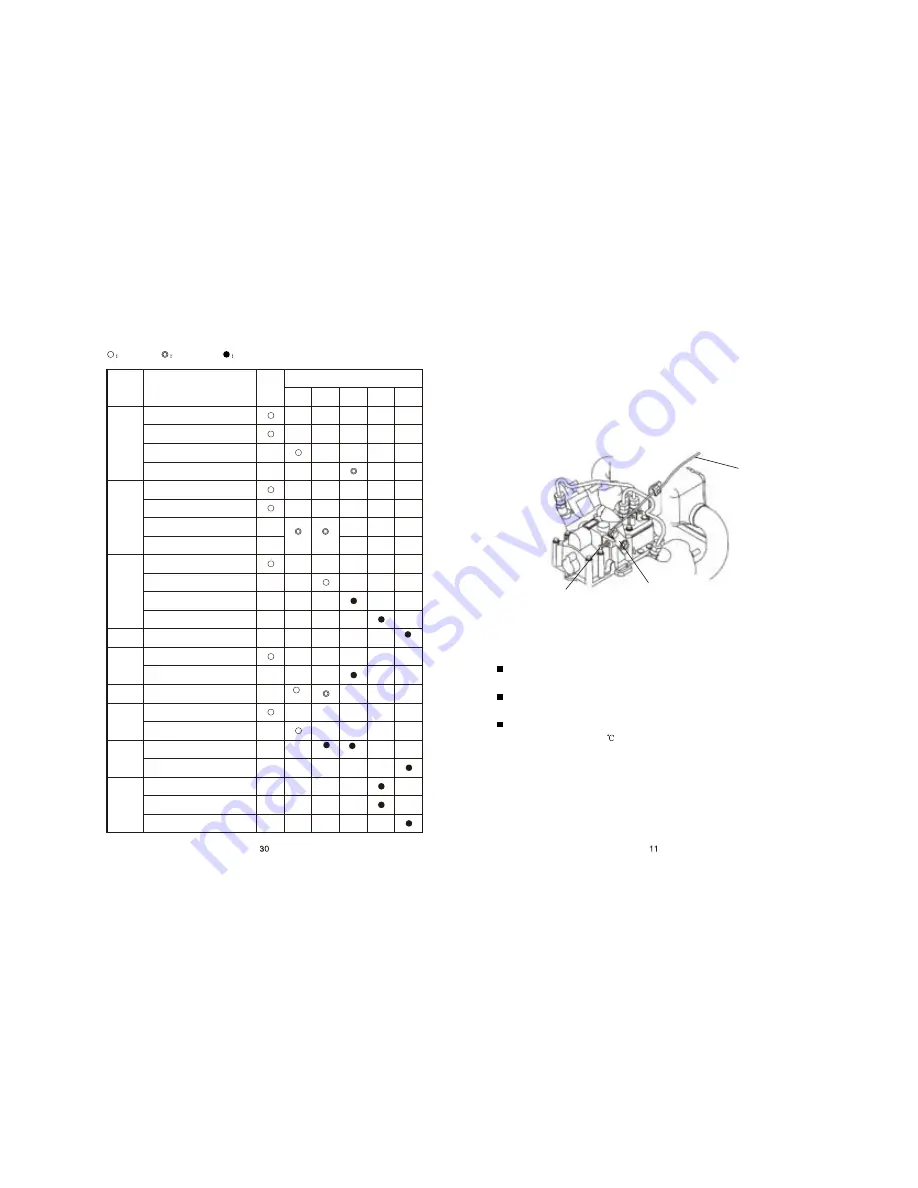

(4) Governor

Controls the engine speed via the control lever. It is linked with the accelerator

system on the driven machine side (accelerator handle and pedal to be procured

by the users) by means of an accelerator wire for remote control.

Move the control lever upward to raise the speed, or downward to decrease it.

Maximum and minimum speeds are restricted by the speed limiting bolts.

(5) Alarm lamp

These lamps notify abnormal states during the engine operation.

Charge warning lamp The lamp is off while the battery is recharged. It goes on

when the battery is not charged normally.

Lube oil pressure warning lamp This lamp comes on if an abnormally low lube

2

oil pressure 4.9 kPa (0.5kgf/cm ) or below is detected by the pressure sensor.

Water temperature warning lamp This lamp lights when the cooling water

temperature rises above 110 .

-

-

Accelerator wire

Control lever

Speed limiting bolt

Check

Replace

Consult KAMA dealer or distributor

Initial Later

50h

200h

400h

1000h 2000h

Check item

System

Daily

checks

Periodic check intervals

Fuel tank oil level check and addition

Fuel leak from fuel tank

Draining from fuel tank

Fuel filter replacement

Lube oil level

Lube oil leak

Lube oil replacement

Lube oil filter element replacement

Check & addition of cooling water

Rediator fin cleaning

Cooling water replacement

Accelerator operation

ldling speed adjustment

Alarm operation check

Fuel injection pump maintenance

Fuel oil

Lube oil

Cooling

water

Rubber

hoses

Operating

system

Intake

system

Electrical

parts

Cylinder

head

Fuel valve

pump

Cooling water path flushing &

maintenance

Fuel oil pipe & cooling water

pipe replacement

Air cleaner element cleaning &

replacement

Battery electrolyte check &

recharging

Fuel injection timing check &

adjustment

Intake and exhaust valve head

clearance adjustment

lntake and exhaust valve seat

lapping

Injection valve pressure check &

adjustment

or 2 years

Cleaning

Initial Later

-

-