User Manual

OB-22/2 LT

18

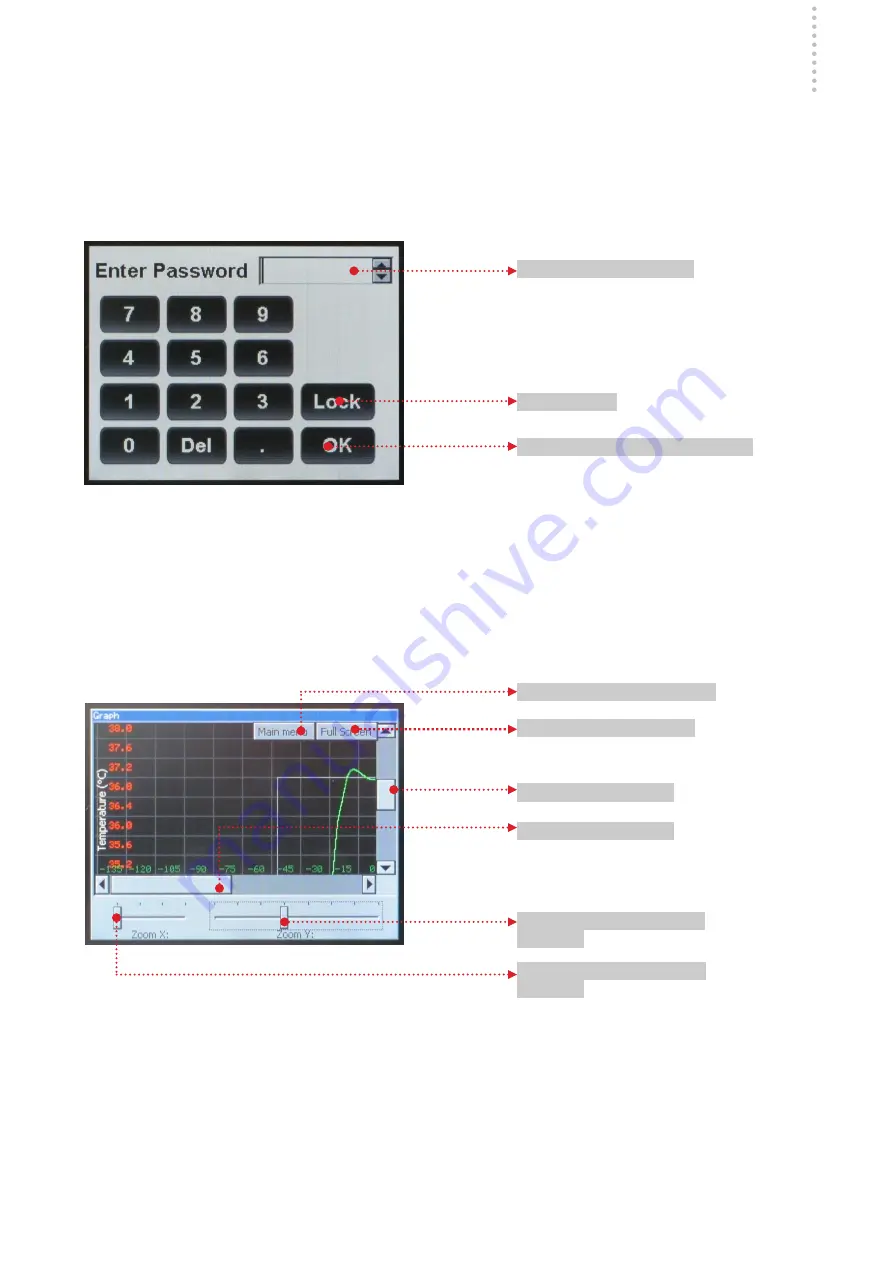

4.2.3 Unlock screen

Press Unlock button to see this screen:

Enter unlock code 0207 and confirm with OK button to enable edit PID settings and temperature corrections.

To disable edit PID setting and temperature corrections press Lock button.

If you forget to press Lock button after 2 minutes it locks automatic.

4.2.4 Graph screen

Press Graph button to see this screen:

Enter unlock code 0207

Press to Lock

Press OK to confirm and unlock

Enter full screen button

Back to Main menu button

Slider to move graph

Slider to zoom graph in y

direction

Slider to move graph

Slider to zoom graph in x

direction