TIP

Assembly, installation and operating instructions

38

11

Faults

The following chapter describes possible causes of faults and the work needed to rectify them. Should faults occur frequently,

shorten the maintenance intervals in line with the actual loading on the unit.

Contact the manufacturer with any faults that cannot be rectified using the following information.

Behaviour in the event of faults

The following applies:

1. Immediately switch off the unit with faults that pose an immediate danger to persons or property!

2. Determine the cause of the fault!

3. Switch off the unit and prevent it from being reconnected if rectifying the fault requires work in the hazard area. Immedi-

ately advise a supervisor on site about the fault.

4. Either rectify the fault yourself or have it repaired by authorised personnel, depending on the nature of the fault.

The

provides information on who is authorised to rectify and remedy faults.

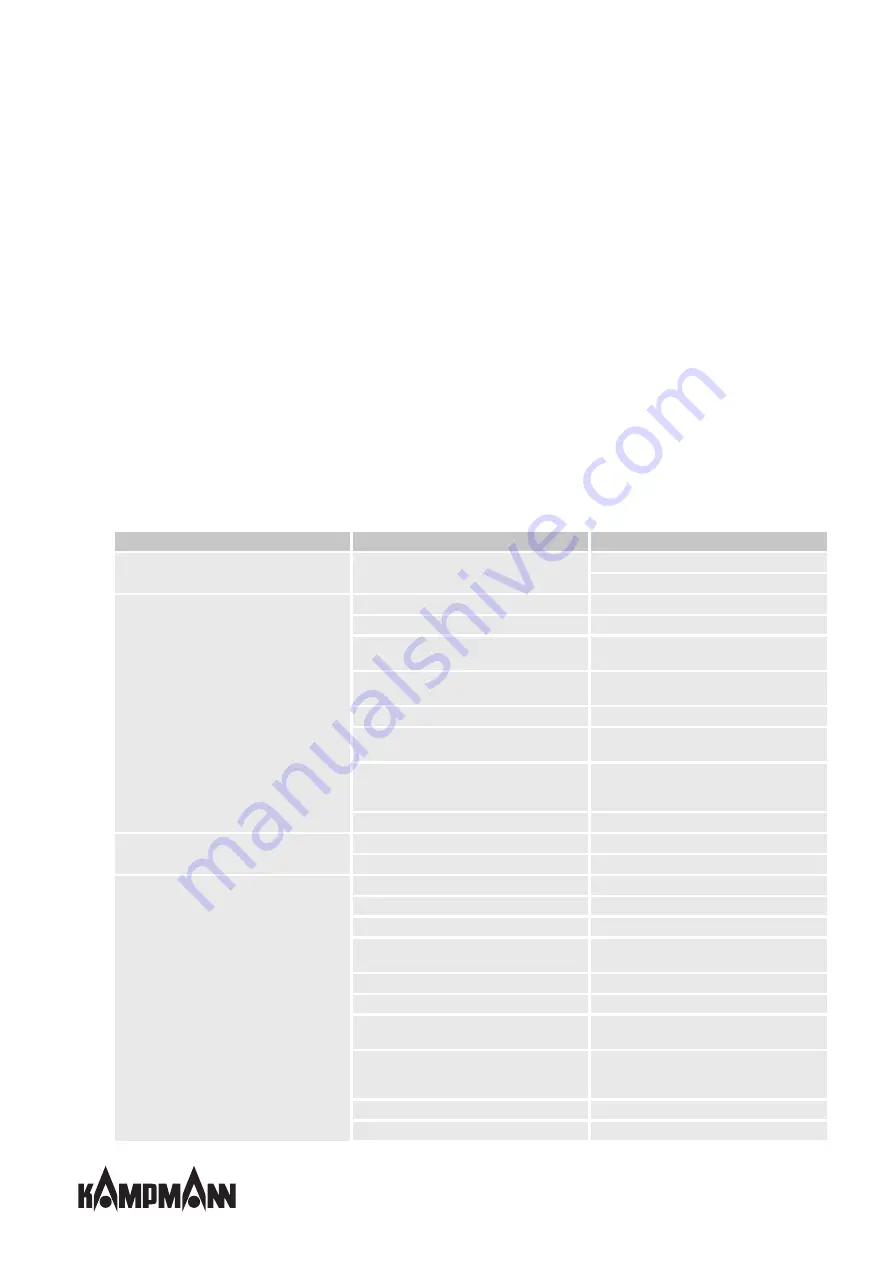

11.1 Fault table

Fault

Possible cause

Remedy

No function.

No power supply.

Check voltage, switch on repair switch.

Replace fuse.

Fan is not running.

Unit is switched off.

Switch on the unit via the controller.

No power supply.

Check power supply and connect.

Electrical cable not connected or incorrectly con-

nected.

Check electrical connection and correct if neces-

sary.

No request from controller, hence fans switch

off.

Change controller settings, if required.

Fan blocked.

Clean dirt from fan.

Impermissible operating pressure (e.g. excessive

back pressure)

Correct operating point. Allow unit to cool

down.

Temperature monitor has tripped.

Allow the motor to cool down, find and rectify

the cause of the fault and release restart lock if

necessary.

Motor winding interrupted.

Replace unit.

Water outlet

Fault on the heat exchanger.

Replace the heat exchanger if you need to.

Hydraulic connection not properly done.

Check flow and return and tighten, if necessary.

Unit is not heating sufficiently (LPHW)

Fan is not switched on.

Switch on fan at controller.

Air volume is too low.

Set a higher speed.

Filter is dirty.

Replace filter.

No heating or cooling medium.

Switch on heating and/or cooling system, switch

on circulation pump, vent unit/system.

Valves not operating.

Replace faulty valves.

Water volume too low.

Check pump output, check hydraulics.

Setpoint temperature on the controller set too

low.

Adjust temperature setting on the controller.

Operating unit with integral sensor and/or ex-

ternal sensor is exposed to direct sunlight or po-

sitioned over a heat source.

Place operating unit with integral sensor and/or

external sensor in a suitable position.

Air cannot blow out or in freely.

Remove obstacles at the air outlet/air inlet.

Heat exchanger dirty.

Clean heat exchanger.

Summary of Contents for TIP

Page 2: ......

Page 40: ...TIP Assembly installation and operating instructions 40 12 Certificates...

Page 45: ......

Page 46: ......

Page 47: ......