28

1.54

Ultra

Comfortable indoor climate in high-end interiors

Installation and operating instructions

Control signal Ultra speed

0-1.0 V

OFF

1.0-9.5 V

0-100 %

9.5-10.0 V

100 %

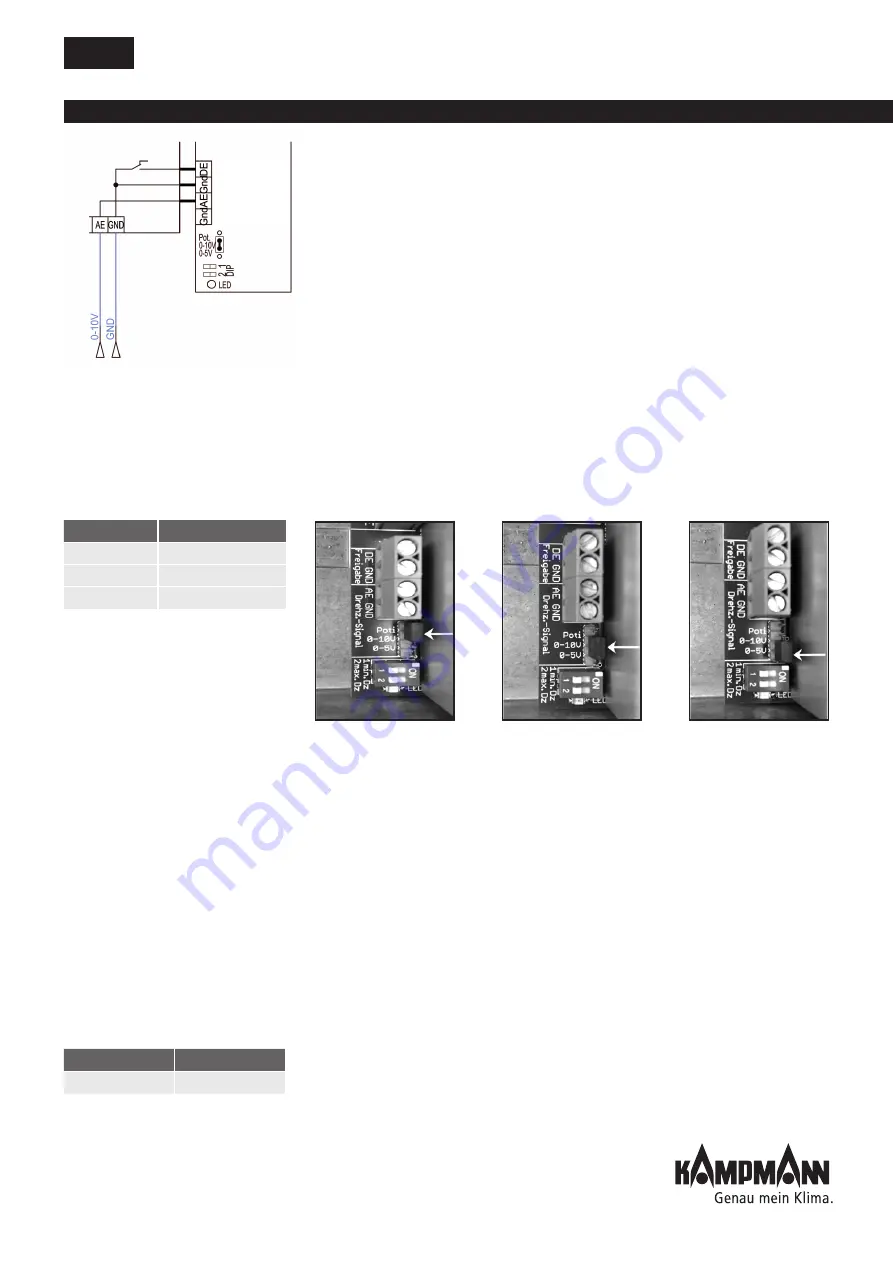

Connection example 0-10 V

Table 2

Control via 0-100a 0-100 KΩ potentiometer

When controlling using a 0-100 KΩ potentiometer (linear), the jumper

on the master unit (the Ultra connected to the potentiometer) must be

connected to the potentiometer (see Fig. 3). All other Ultras (slave units)

should then have jumper position 0 - 5 V (see Fig. 3).

Control via 0-10 V DC

When controlling with 0-10 V DC, the jumper must be connected to 0-10 V

on all power units (refer to Fig. 2). The 0 - 10 V control signal is interpreted

with respect to its speed according to the table (refer to table 2). Input

resistance Ri > 100 kOhm.

Control via 0-5 V DC

When controlling with 0-5 V DC (for instance control by others), the

jumper must be connected to 0-5 V on all power units. The speed does not

behave linear to the control voltage with this setting (refer to Fig. 3). Input

resistance Ri > 100 kOhm.

Fault signal output

In addition to the motor fault signal alluded to in the paragraph

”Continuously variable power module type ...V“ in Chap. 10.2.1, the

overheating of the power module is signalled via the potential-free N/C

(60 V AC/DC max. 1 A). In the event of a fault, the control signal has to be

locked to 0 V via the controller.

Voltage supply and fuse

The fan and power module are together supplied by one line with

230 V/50 Hz voltage. An operating indicator LED is positioned on the

connecting PCB in the power module.

A unit fuse Ø5x20 mm is also installed as a main fuse on the connecting PCB

and a TR5 fuse on the power PCB. Refer to Table 3 for values. Maximum

on-site fuse 10 A.

Fig. 1:

Jumper to

potentiometer

Fig. 2:

Jumper to 0 - 10 V

Fig. 3:

Jumper to 0 - 5 V

Connecting PCB

Power PCB

T2.5 A

F2.5 A

Table 3

Activation

Speed signal

Control signal

for fan speed

0..10 V D