Venkon XL

Beschreibung

Assembly, installation and operating instructions

34

7.2

Electromechanical control, Venkon XL

7.2.1 Connection (*00 or 00D), Venkon XL

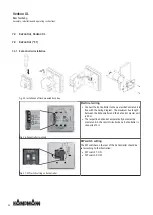

Fig. 33: Remove junction box from the Velcro

strip

The junction box for the electromechanical control can be removed from the side

panel of the basic unit by Velcro fitting. Simply remove the plastic lid to open

the junction box.

Description of wiring

Factory-fitted actuators are wired to the terminal. The appropriate terminals are available for valve drives on site.

The speed of EC fans used is continuously variably controlled by a 0 – 10 V DC signal. The”intelligent” motor electronics

detects any possible motor fault and automatically switches the fan off.

Fig. 34: Venkon XL socket

Note these points in the following wiring diagrams for Venkon XL with electromechanical control:

Comply with the details on type of cable and cabling taking into consideration VDE 0100.

None *: NYM-J. The requisite number of wires including fuse is stated on the cable. Cross-sections are not indicated as

the cable length is involved in the calculation of the cross-section.

With *: J-Y(ST)Y 0.8mm. Lay separately from high-voltage cables.

If you are using different cable types they must be at least equivalent to these.

The terminals on the unit are suitable for a maximum wire cross-section of 2.5 mm².

Only pulse and/or all-current sensitive residual current protective devices (type A or B) are permitted when using residual

current protective devices. When power is applied to the unit, pulse-like capacitor load currents in the integrated EMC

filter can lead to the RCCB being immediately tripped. We recommend residual current protective switches with a

threshold of 300 mA and delayed triggering (super resistant, characteristic K).

The

listed in the following table needs to be considered when configuring the on-site mains sup-

ply and fuses.

Summary of Contents for Venkon XL

Page 2: ......

Page 5: ...5 13 2 ERP Datenblatt Venkon XL 70...

Page 67: ...Venkon XL Beschreibung Assembly installation and operating instructions 67 13 Certificates...

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ...www kampmanngroup com hvac products fan coils venkon xl 02 20 ENSAP Nr 1374732...