MANUAL COMPLIANCE

Technical maintanance, operation and TM K&S Basic generator

storage are to be performed according to this manual recommen-

dations. Manufacturer bears no responsibility for damages and

losses, caused by incompliance to safety requirements and tech-

nical maintanance rules.

IMPORTANT!

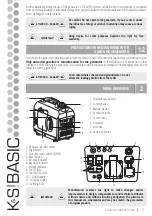

TECHNICAL MAINTENANCE WORKS

Unit

Action

At each start

First month

or 20

operating hours

Every 3 months or 50 operating

hours

Every 6 months or 100 operating

hours

Every year

or 300 operating

hours

Motor oil

Level check

Replacement

Air filter

Check /

Cleaning

Replacement

Spark plug

Cleaning

Replacement

Fuel tank

Level check

Cleaning

Fuel filter

C

heck (clean out)

- If the generator often operates at high temperature or high load, the oil should be replaced every 25 operating hours.

- If the engine often runs in dusty or other harsh conditions, clean the air filter every 10 operating hours.

- If you missed the maintenance time, perform it as soon as possible to save the generator engine.

Motor oil has a serious impact on performance charac-

teristics and is a major attribute, defining its service life.

Use oils designed for four-stroke cycle vehicle engines,

since such oils contain cleaning additives, which comply

or even exceed SE standards according to API classification

(or equivalent).

RECOMMENDED OILS

10

0

00

CC

10W-30, 10W-40

40

40

30

30

20

20

10

10

-10

-10

-20

-20

In general, the engine is recommended to run with motor oils of SAE10W-30, SAE10W-40 viscosity level. Motor oils

with other viscosity levels, may be used only if the average air temperature in your region does not exceed the limits

of the temperature range, specified in the table. Oil viscosity according to SAE standards or service category, are

specified on the API capacity sticker.

Stop the engine before servicing. Place the generator on a flat

surface and remove the spark plug cap to prevent starting the

engine.

ATTENTION - DANGER!

koenner-soehnen.com

|

8