18

Service and Repair Manual

Model 1400KV/1400BV

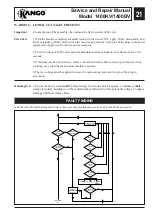

Fig. 33

Fig. 31

Fig. 32

INSERT A

Assembling

the Inclined

Shaft Bearing

Assembly

1.

Fit the Inclined Shaft Bearing (46) to the Service

Tool and fit the layshaft (47). Press the layshaft

until seated.

Note:

Flange on bearing is fitted to flange

on layshaft.

2.

Locate and fit the gear (48) and the taper forward

roller bearing (41) and press on both items to

layshaft assembly (47).

3.

Fit taper roller bearing (41) onto layshaft

assembly.

Refitting the

Inclined Shaft

Bearing

Assembly

Note:

Lubricate (34) and (46) layshaft assembly as

shown in the lubrication diagram.

1.

Fit the eight concave spring washers (39) into the

Hammer Case bearing housing (34) as follows:

2 x facing inward

}

2 x facing outward

}See insert (A)

2 x facing inward

}

2 x facing outward

}

2. Place steel washer (40) on to the spring washer

assembly (39). Fit the bearing outer (41).

3.

Insert the ISB assembly (A) into the Hammer

Case (34) ensure the inclined shaft (46) engages

with the piston gudgeon pin. Ensure the assembly

fits into the bearing housing (34).

A

46

47

A

41

41

A

41

34

39

40

41

46

48

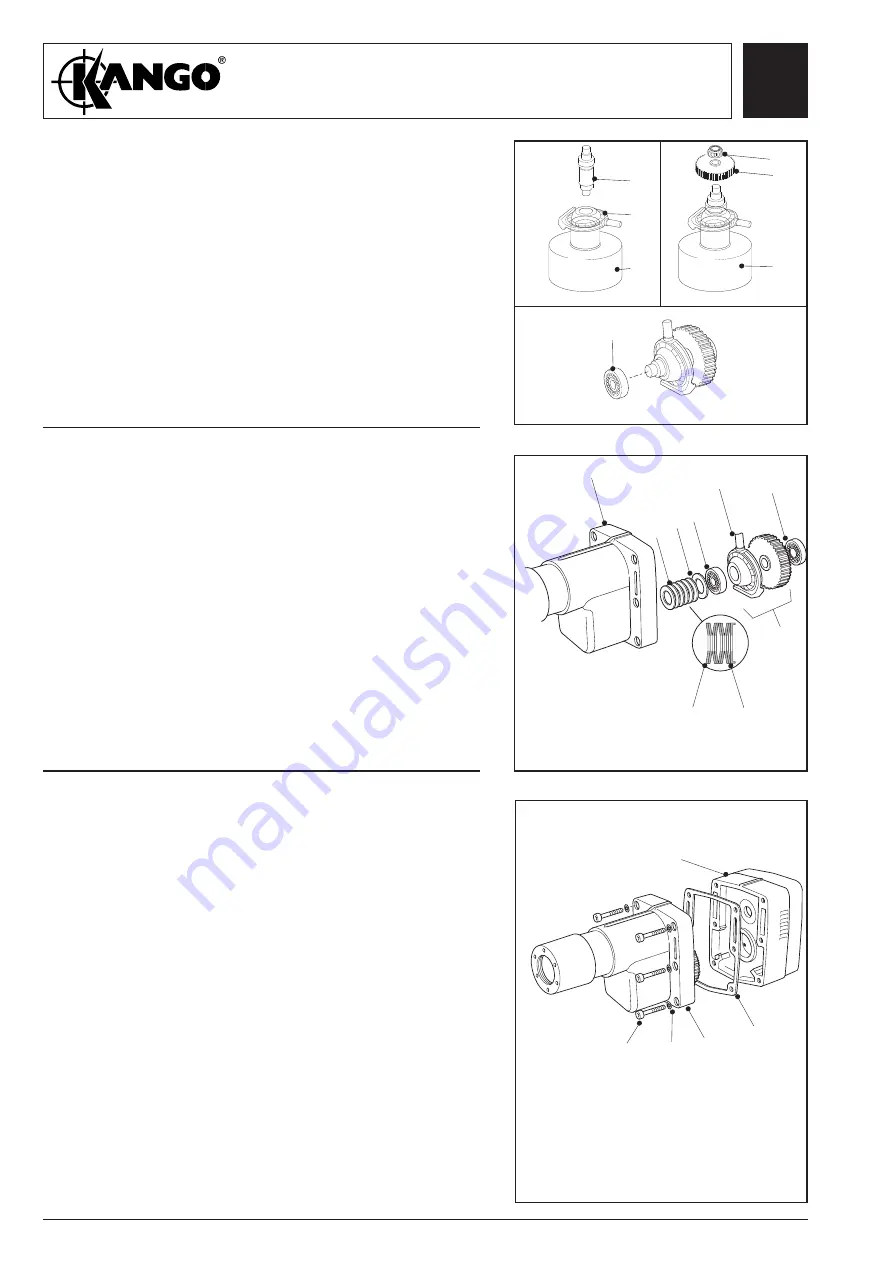

Note:

Lubricate bearing housing (50) as shown in

the lubrication diagram.

1.

Align the gasket (49) to the hammer case (50)

assembly. Ensure correct orientation.

2.

Fit the bearing housing (50) to the hammer case

(34) ensure engagement of gears.

3.

Secure the two halves with the six Allen bolts

(35) and washers (36).

(Torque load to 30 Nm).

Fitting the

Hammer

Case

Assembly

35

34

49

50

36

39

40

Summary of Contents for 1400 Series

Page 1: ......