13

Service and Repair Manual

Model 1400KV/1400BV

General

For best performance hammers should be serviced at regular intervals, any indication that the hammer is

not performing as specified should be investigated to prevent any adverse damage occurring.

ALL SEALS, GASKETS, GREASE OR OTHER PARTS DEEMED NECESSARY FOR

SERVICING ARE IN THE SERVICE KIT.

ALL NEEDLE ROLLER BEARINGS SHOULD BE PRESSED WITH THE ROUNDED

EDGE ENTERING THE BORE FIRST, AND THE PRESS TOOL PRESSING AGAINST

THE FLAT SURFACE OF THE BEARING.

Cleaning

All mechanical parts with the exception of any sealed bearings should be cleaned in a suitable cleaning

fluid. Electrical parts should be cleaned by the use of compressed air.

PRECAUTIONS MUST BE TAKEN FOR PERSONAL SAFETY THE USE OF EYE

PROTECTION AND GLOVES IS RECOMMENDED.

Inspection

All mechanical and electrical parts should be inspected for wear and replaced as required.

Lubrication

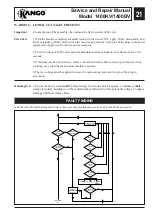

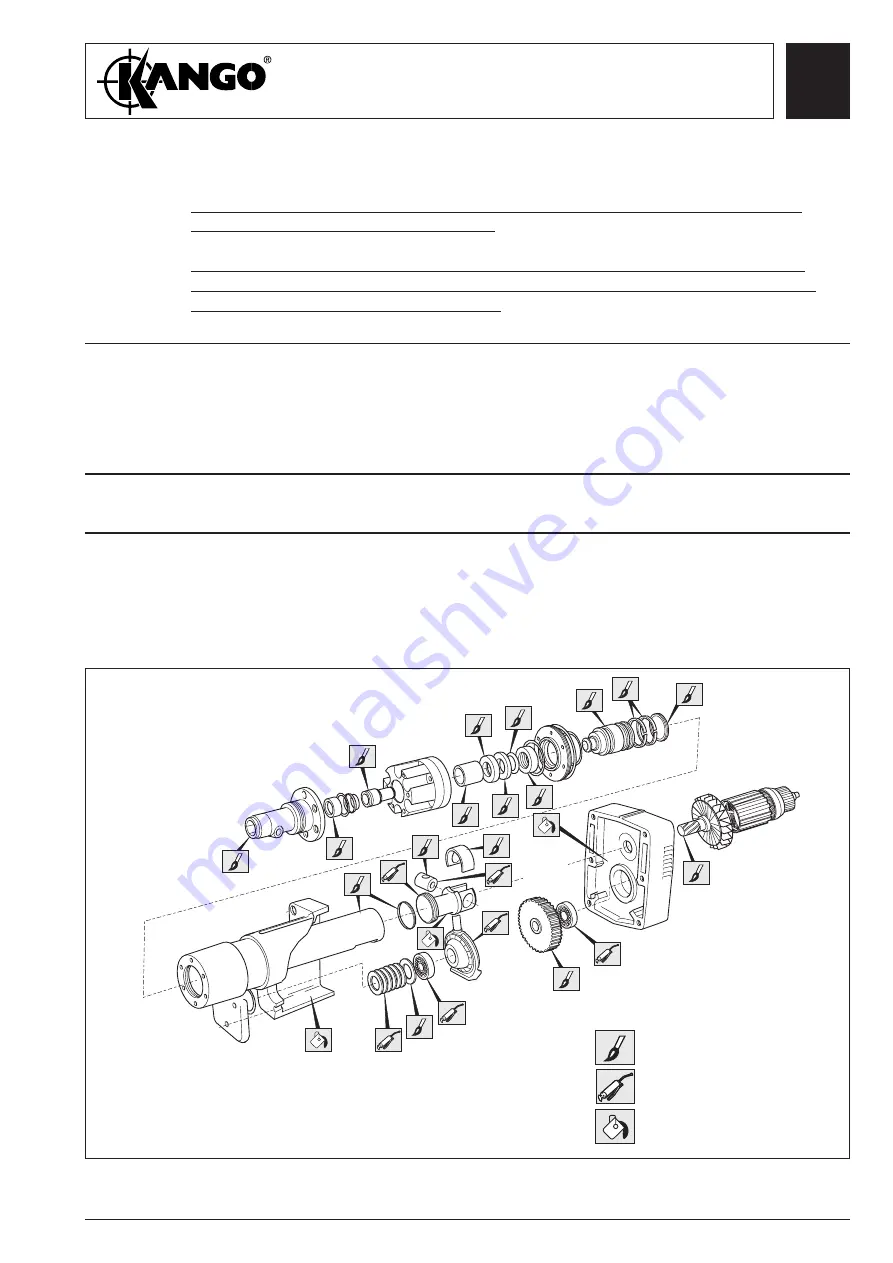

At service and repair intervals the lubrication should be carried out as shown in the diagram below. All

parts in the service kit should be fitted. The total amount of grease for the 1400 is 390 grms

(9170304323, blue). Lubrication of the hammer is as shown on the grease chart.

ALL SCREWS SHOULD BE REFITTED WITH LOCKTITE

®

271 OR SIMILAR

(at 45° from

centre to

outside)

1.5 x 85gms

Liberally coat

GREASE APPLICATION CODE

GREASING PROCEDURE - 1400

Pack

Generously coat

Summary of Contents for 1400 Series

Page 1: ......