30

Service and Repair Manual

Model 710/760

Fig. 49

1.

Fit seals (92) to anvil (91).

2.

Insert anvil assembly to anvil sleeve (93).

3.

Fit O-ring (87) to catcher (88).

4.

Assemble to transmitter housing.

- catcher assembly (87 and 88)

- buffer ring (89)

- recoil transfer ring (90)

- anvil sleeve assy (91-93)

- O-ring (95)

5.

Fit O-ring (94) into nosepiece (96).

6.

Secure nosepiece to transmitter housing (85) with

screws (101)

torque load to 10Nm.

Assembling

the nosepiece

101

96

95 94

93

92

91

(710KV)

91

(710BV)

90

89 88

87

85

Service and Repair Manual

Model 710KV/710BV

710KV/710BV ASSEMBLY

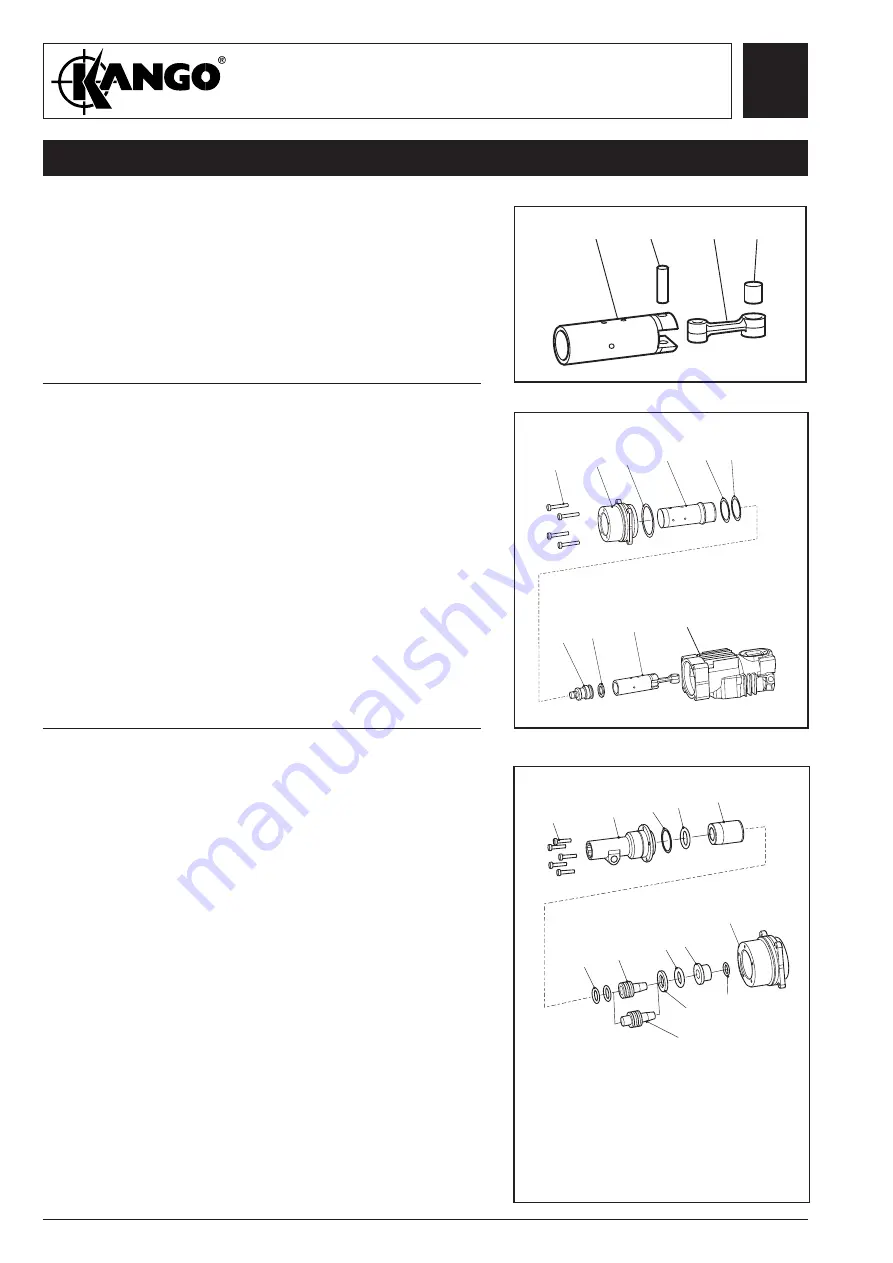

Fig. 47

Fig. 48

1.

Fit bearing (74) into connecting rod (114).

2.

Position connecting rod (114) to piston (77) and

fit gudgeon pin (76) to secure.

Assembling

the piston

1.

Assemble the following items to the transmitter

housing (85):

- O-ring (84)

- barrel (83)

- washer (82)

- shim (81)

- striker (79)

- striker seal (78)

- piston assembly (77)

2.

Fit the barrel assembly and transmitter housing

assembly (85) to top housing (73), and secure

with four screws (86)

torque load to 15Nm

.

Assembling

the barrel

77

76

114

74

86

85 84

83

81

79 78

77

82

73

Summary of Contents for 710 Series

Page 1: ......