Service and Repair Manual

Model 845S

6

FIG.

%

NOTES

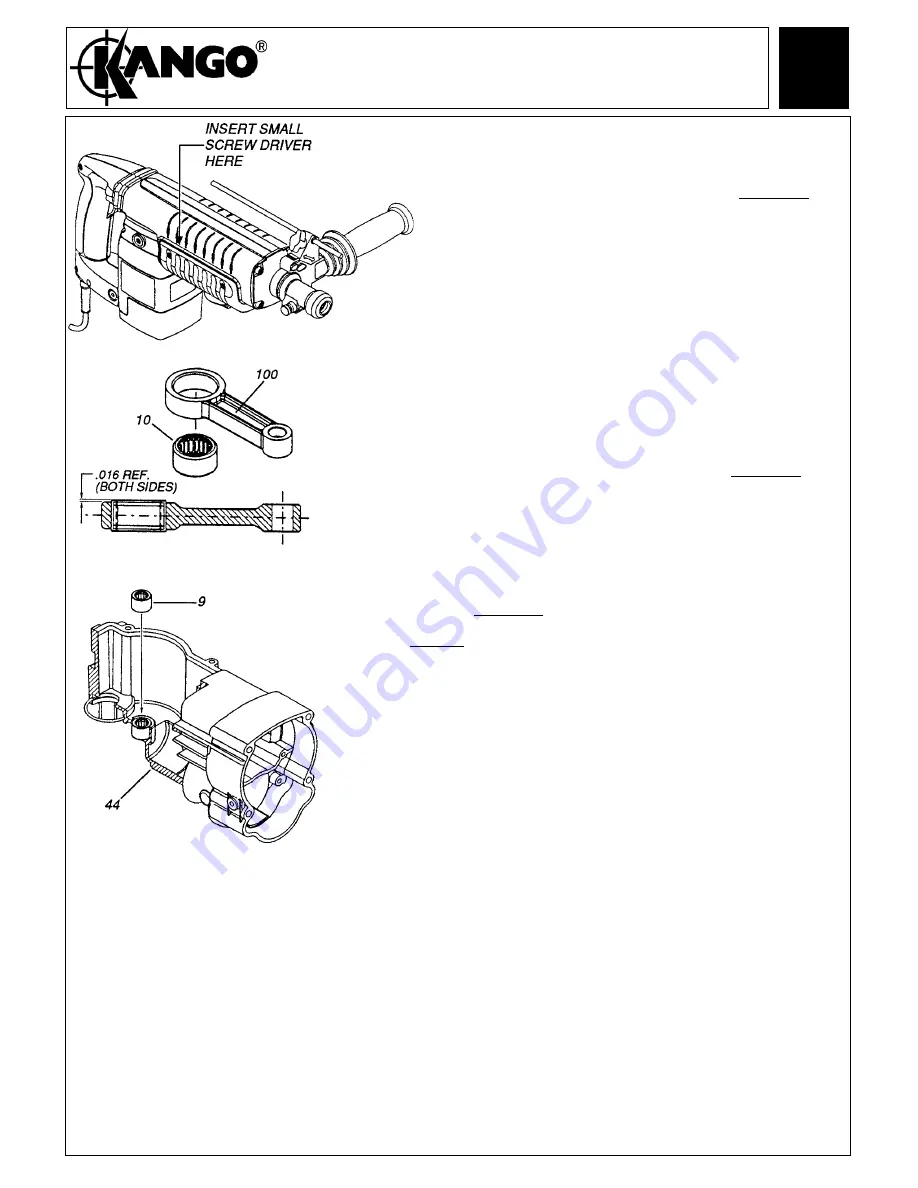

54, 55, 56 TO REMOVE BELLY SHROUD #56 FROM TOOL, INSERT SMALL SCREW

DRIVER INTO GROOVE BETWEEN BELLY AND SIDE SHROUDS #54 AND

#55, ABOUT 1/3 OF THE WAY FROM THE MOTOR END, AS SHOWN. PRY

OUT AND DOWN ON BOTH SIDES OF THE TOOL.

54, 55

TO INSTALL THE SIDE SHROUDS #54 AND #55, THE TOP HINGE OF THE

SHROUDS MUST BE COMPLETELY INTERLOCKED, THEN THE BACK

SIDE ROTATED CLOSED AROUND THE TOOL.

73

LUBRICATE ALL BORES IN SPINDLE #73 WITH A MEDIUM COATING OF

GREASE.

63, 108, 109 LUBRICATE RUBBER DAMPING WASHER #63, BARREL THRUST

WASHER #108 AND STRIKER CUSHION WASHER #109 WITH A MEDIUM

COATING OF GREASE BEFORE ASSEMBLY.

10, 100

PRESS NEEDLE BEARING #10 IN ROD #100 SO THAT THE SAME

AMOUNT STICKS OUT ON BOTH SIDES OF THE ROD, AS SHOWN.

9, 71

PRESS (2) NEEDLE BEARINGS #9 INTO HOLLOW CLUTCH SHAFT #71,

FLUSH WITH THE ENDS OF THE SHAFT.

11, 12, 46 PRESS NEEDLE BEARINGS #11 AND #12 FLUSH TO THE MACHINED

FACES ON BOTH ENDS OF THE INTERMEDIATE HOUSING #46.

9, 44

PRESS NEEDLE BEARING #9 INTO CRANKCASE #44, FLUSH WITH TOP

OF BORE, AS SHOWN.

81

LIGHTLY GREASE INSIDE OF BARREL #81 BEFORE ASSEMBLY.

48, 73

SMALL OUTSIDE DIAMETER OF SPINDLE #73 IS TO BELUBRICATED

WITH A LIGHT COAT OF GREASE BEFORE ASSEMBLING THE NOSE

ASSEMBLY #48 TO THE TOOL.

48, 73, 102 NOSE ASSEMBLY #48 MUST BE PLACED SQUARELY OVER SPINDLE #73,

WHEN ASSEMBLING, TO PREVENT DAMAGE TO OIL SEAL #102.

14, 19, 20, 23 FASTENERS #14, #19, #20 AND #23 ARE TO BE RE-ASSEMBLED USING

BLUE LOCTITE.

48, 102

LUBRICATE BORE IN NOSE ASSEMBLY #48 BEFORE PRESSING OIL

SEAL #102 INTO PLACE.

60, 61, 62, LUBRICATE O-RINGS #60, #61, #62, #66 AND #67 WITH GREASE.

66, 67

69

INSTALL BEVEL SNAP RING #69 WITH BEVEL SIDE UP.

4, 50, 80

PLACE BEARING CUP #80 ON SMALL ARMATURE BEARING #4 BEFORE

INSTALLING MOTOR COVER #50.

41

BRUSH SPRINGS #41 ARE TO BE WOUND 1/2 TURN TO ENGAGE

BRUSHES.

4

RUBBER SEAL SIDE OF BALL BEARING #4 TO FACE FAN.

95, 98

FACES OF PISTON #95 AND RAM #98 ARE TO BE FREE OF GREASE.

105

WHEN REASSEMBLING BARREL AND CLUTCH SCREWS INTO EXISTING

CRANKCASE, MAKE SURE SCREW IS STARTED IN EXISTING THREAD.

DO NOT CREATE TWO SETS OF THREADS IN ONE HOLE.