12

PAGE

Repair Instructions

K 350

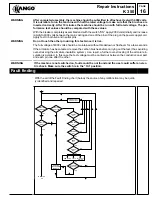

Assembling the

angle drive

1

Insert the support ring (71).

2

Grease the shaft (82) and insert into the

gear box (27) by turning it slightly.

3

Insert the disks (72 &73).

Note: Depending on the tolerance of the

bearing, two or three disks (72 &73) are

needed. For assembly, use the same

amount of disks as removed.

4

Insert the locking washer (67) such that

the lugs face the bearing (see illustration).

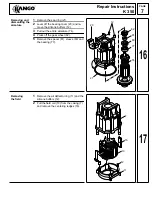

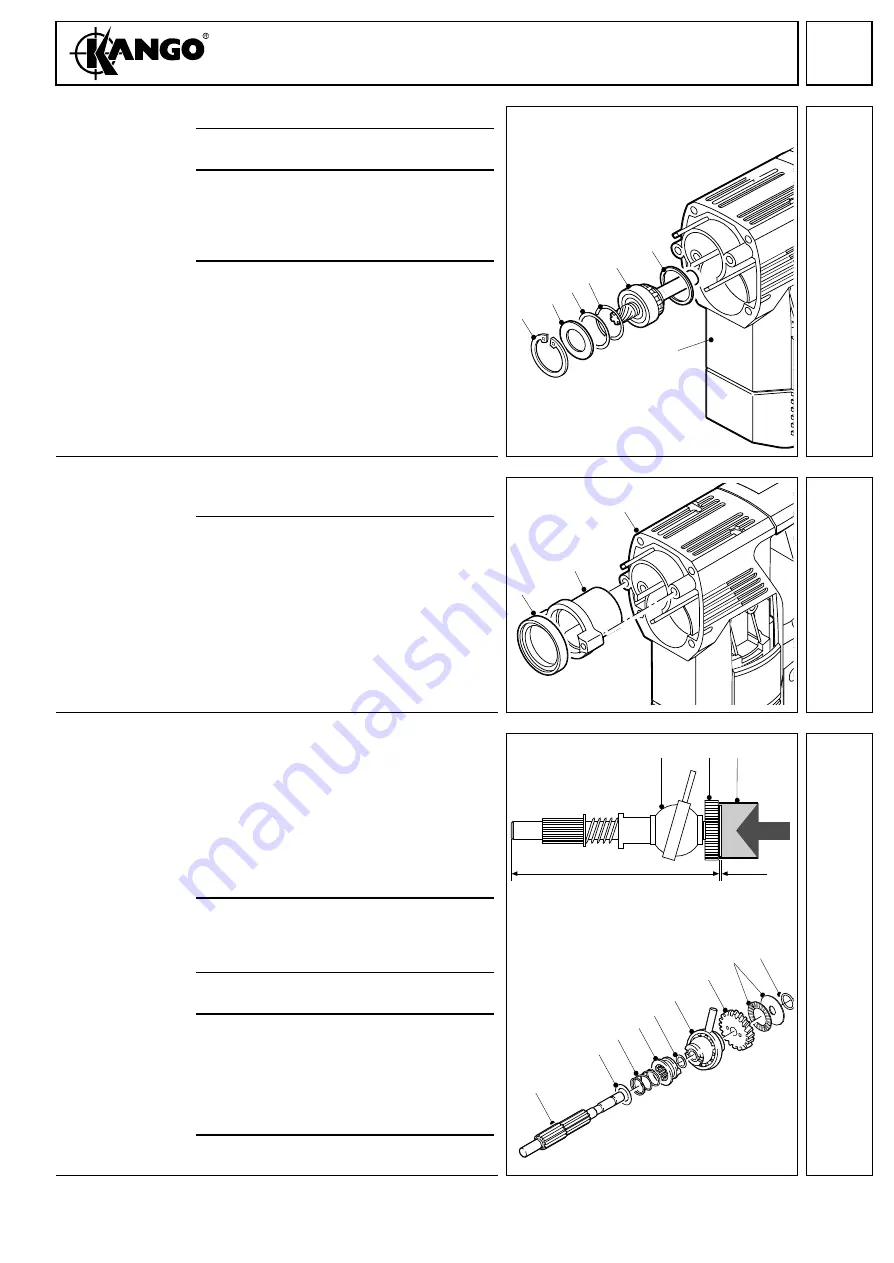

Mounting the

spindle bearing

1

Press the sintered bearing (69) into the

bearing housing (70).

2

Insert the bearing housing (70) into the

gear box (27).

Note: Do not press in the bearing hous-

ing (70) completely for easier mounting of

the back shaft (29) and the cylinder (40).

Caution: Care must be taken to ensure

the correct positioning of the bearing

housing (70).

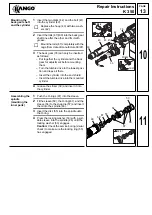

Assembling the

back gear shaft

1

Fit the following parts onto the back of re-

duction gear shaft (29) in the following or-

der:

– disk (31)

– spring (32)

– coupling sleeve (33)

– disk (34)

– tumble drive (35)

2

Press on the reduction gear (36) with

0.05 mm to the tumble drive.

Caution: the smooth surface must face

the tumble drive (35).

3

Lightly grease the thrust bearing (30) and

insert it into the reduction gear (36).

4

Fit the disk (30) and check the distance:

– if the distance is more than 100.5mm, do

not fit the disk (30).

– if the distance is less than 100.5mm fit

another disk (30) and check the dis-

tance again.

5

Push on the O-ring (87).

67

66

82

71

27

72

73

7

69

70

27

8

X

0,5 mm

35

36 30

29

31

32

33

34

35

36

87

30

9

Summary of Contents for K 350

Page 1: ......