16

PAGE

Repair Instructions

K 350

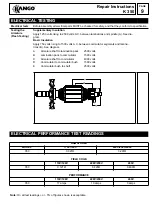

WARNING

After completed assembly, the machine should be submitted to a flashover test with 4000 volts.

It is advisable to run the machine with half the rated voltage to make sure that the brushes are

inserted correctly. After 10 minutes the machine should be run with full rated voltage. The per-

formance test values should be compared with these values.

With the breaker completely assembled and with the switch “ON” apply 2000 volts initially and increase

rapidly to 4000 volts between the main casting and one of the pins of the plug on the power supply cord.

Apply test to both live and neutral pins.

WARNING

Do not touch the other pin during this test since it is live.

The full voltage of 4000 volts should be maintained without breakdown or flashover for a few seconds.

If the armature has been tested, remove the carbon brushes before carrying out the test, (thus avoiding

over-stressing the armature insulation system.) As a result, a further over-stressing of the armature in-

sulation is avoided. In this case the test voltage must be carried out between the conductive cast part

and each pin one after the other.

WARNING

If the machine is not switched on, faults could be not found and the user could suffer an elec-

tric shock. Make sure the switch is in the “On” position.

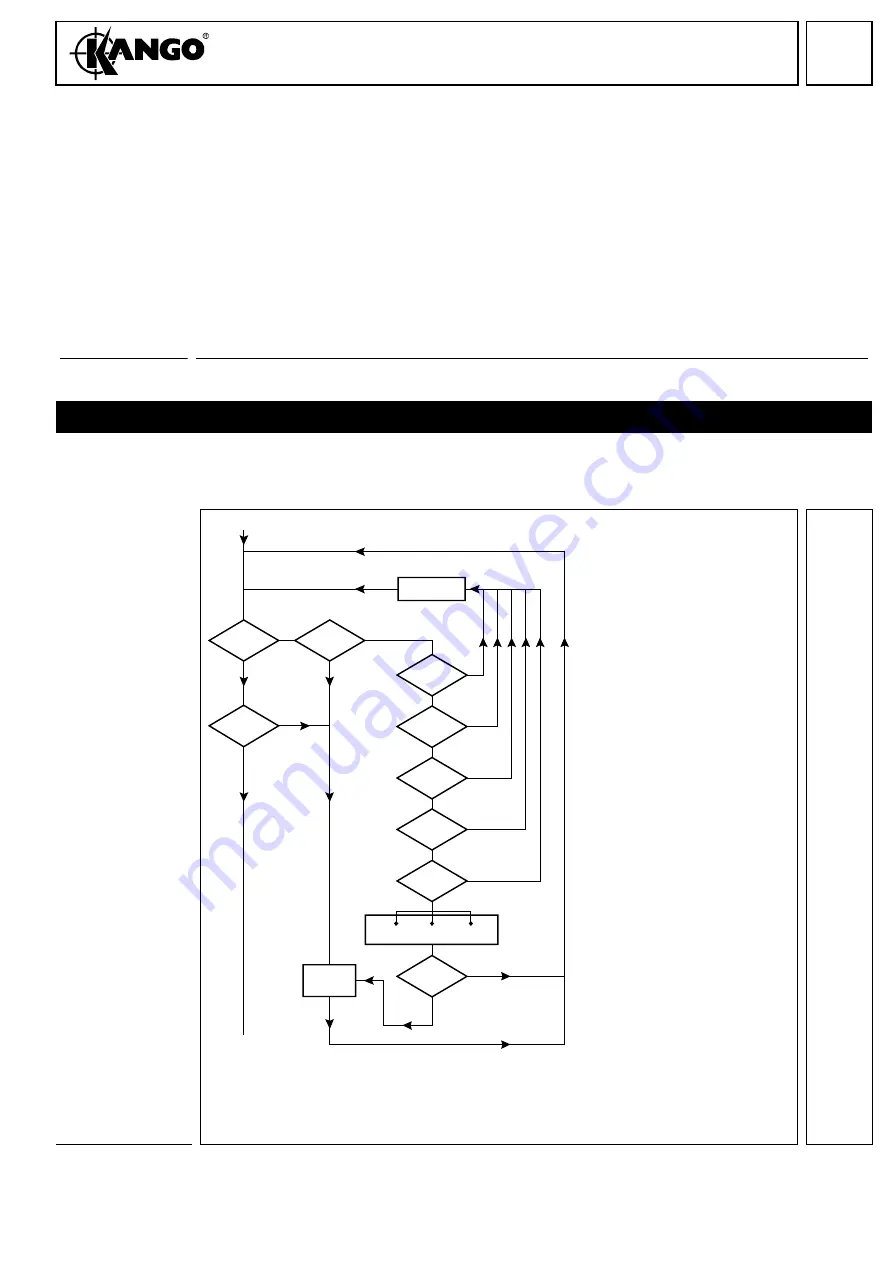

Fault finding

With the aid of the Fault Finding chart (below) the source of any malfunction may be quick-

ly identified and repaired.

REMEDY FAULT

AND RETEST

MOTOR

REVOLVES?

MACHINE

HAMMERS?

MACHINE

IDLES?

SUPPLY

OK?

PLUG FUSE

OK?

BRUSHES

OK?

CORD

OK?

SWITCH

OK?

ARMATURE FIELD

INTERNAL

WIRING

SERVICE

MECHANISM

MODULE

WAS MOTOR

BURNT OUT?

MACHINE

OK

YES

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Summary of Contents for K 350

Page 1: ......