Technical manual

KANMED Operatherm OP3

Page

33

of

34

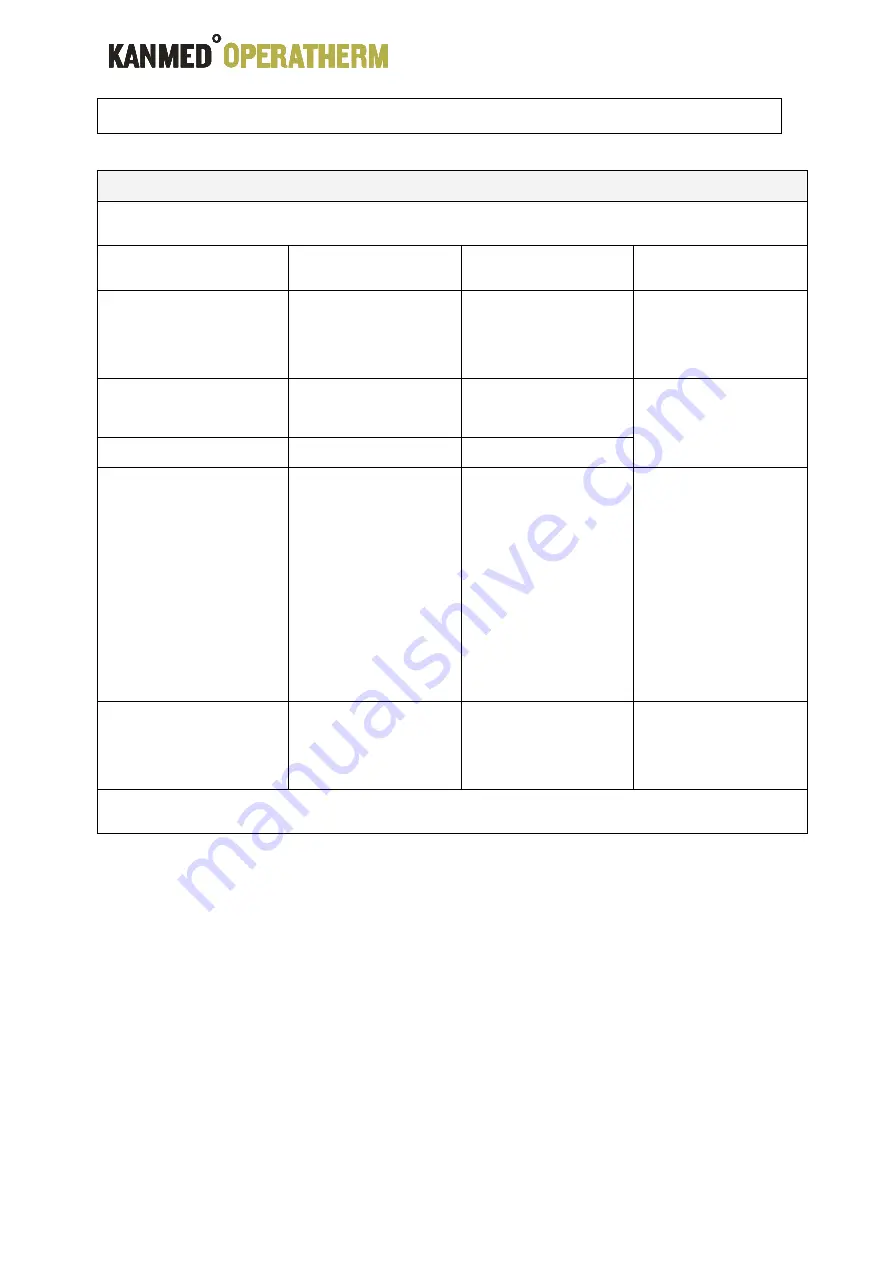

Guidance and manufacturer’s declaration - electromagnetic immunity

The KANMED Operatherm OP3 system is intended for use in the electromagnetic environment specified below.

The customer or the user of the KANMED Operatherm OP3 system assures that it is used in such an environment.

immunity test

IEC 60601 test level

Compliance level

Electromagnetic

environment -

guidance

Electrostatic discharge

(ESD)

IEC 61000-4-2

±6 kV contact

±8 kV air

±6 kV contact

±8 kV air

Floors should be wood,

concrete or ceramic tile.

If floors are covered with

synthetic material, the

relative humidity should

be at least 30%

Electrical fast

transient/burst

IEC 61000-4-4

±2 kV for power supply

lines

±1 kV for input/output

lines

±2 kV for power supply

lines

±1 kV for input/output

lines

Surge

IEC 61000-4-5

±1 kV differential mode

±2 kV common mode

±1 kV differential mode

±2 kV common mode

Mains power quality

should be that of a

typical commercial or

hospital environment

Voltage dips, short

interruptions and voltage

variations on the power

supply input lines

IEC 61000-4-11

<5% U

T

(>95% dip in U

T

)

for 0,5 cycle

40% U

T

(60% dip in U

T

)

for 5 cycles

70% U

T

(30% dip in U

T

)

for 25 cycles

<5% U

T

(>95% dip in U

T

)

for 5 sec

<5% U

T

(>95% dip in U

T

)

for 0,5 cycle

40% U

T

(60% dip in U

T

)

for 5 cycles

70% U

T

(30% dip in U

T

)

for 25 cycles

<5% U

T

(>95% dip in U

T

)

for 5 sec

Mains power quality

should be that of a

typical commercial or

hospital environment.

If continued operation

during power mains

interruptions, it is

recommended that the

KANMED Operatherm

OP3 system be powered

from an uninterruptible

power supply unit (UPS)

Power frequency (50 Hz)

magnetic field

IEC 61000-4-8

3 A/m

3 A/m

Power frequency

magnetic fields should be

at levels characteristic of

a typical location in a

typical commercial or

hospital environment

Note:

U

T

is the AC mains voltage prior to application of the test level