-

2.6

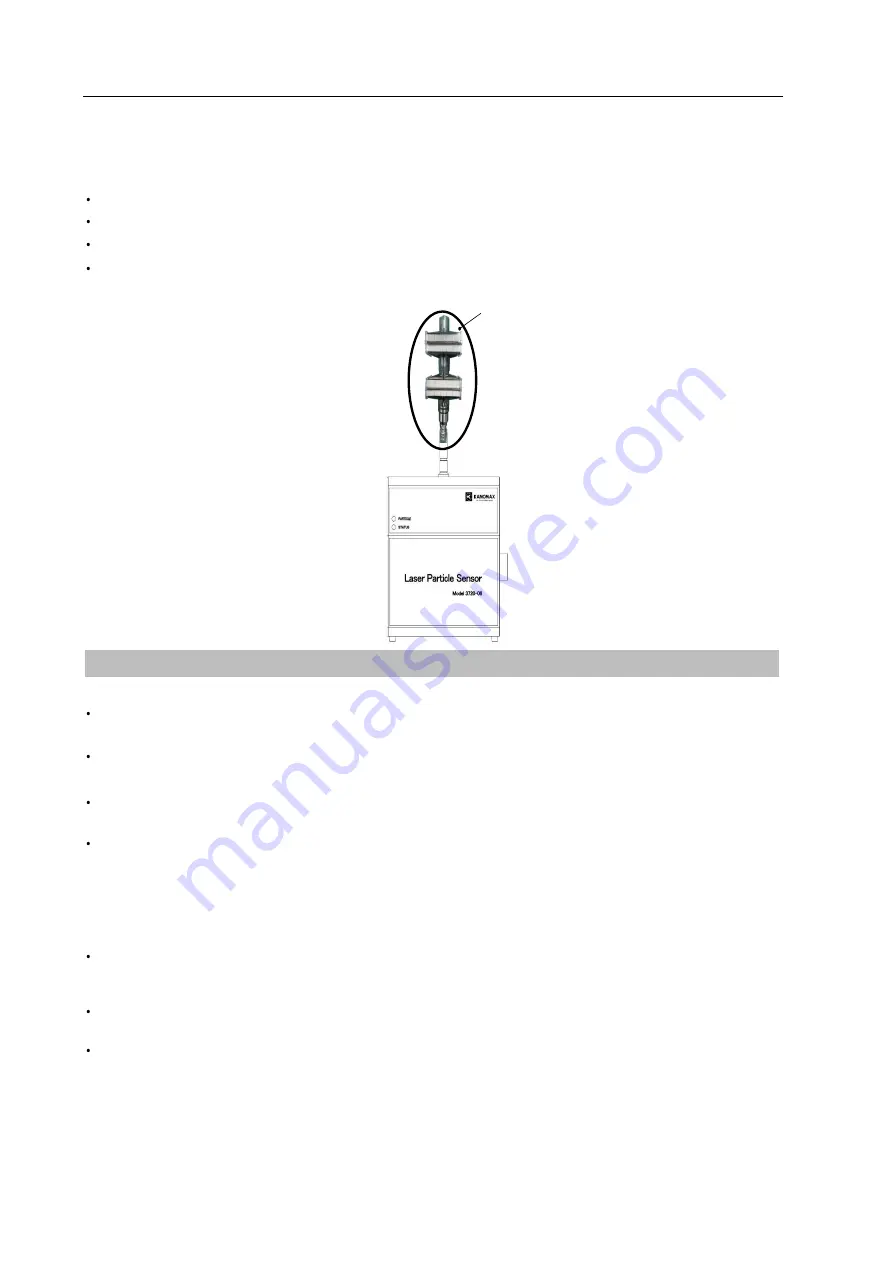

Zero filter connection

Perform a zero check before measurement to verify the cleanliness of the optical system.

Connect the tube side of the filter to the adapter of the main unit.

Handle filters with care.

If air leaks between the filter and the main unit occur, correct zero check will not be

possible.

Zero-point

3. measurem

Make sure that "2. Preparation before measurement" in the instruction manual has

been completed.

For measurement, inhale sample air directly from the inlet of the 3720-06. Also, connect

the supplied Tygon tube to the inlet to inhale sample air.

Turn on the power to the 3720-06. T h e main unit will start measurement with

the parameters already set.

Failure is confirmed by the state of the main unit STATUS lamp, output current value of

the analog output terminal, alarm output state, etc.

If the problem is detected, investigate the cause of the problem by referring to "5. If the problem

persists, contact the place of purchase or KANOMAX. If the problem persists, contact the

place of purchase or KANOMAX.

If protection level IP65 is required, optional IP65 protection case (MODEL

(3720-06-23).

If the built-in vacuum source has exceeded its service life during continuous

operation, replace the pump assembly.

The product is capable of storing 5000 measurement data. Stored data includes storage

time, product status, and particle count values. Data is saved every sampling time

after the product is turned on. After more than 5000 pieces of data have been stored,

they are no longer stored and all stored data can be read back to perform a stored

data deletion operation. See 3720-06 MODBUS Communication Protocol for information

on how to read and erase stored data.

Summary of Contents for 3720-06

Page 1: ...Laser Particle Sensor MODEL 3720 06 Intense Light Particle Sensor User s manual...

Page 22: ......

Page 23: ......