【

9

】

STITCH FORMATION

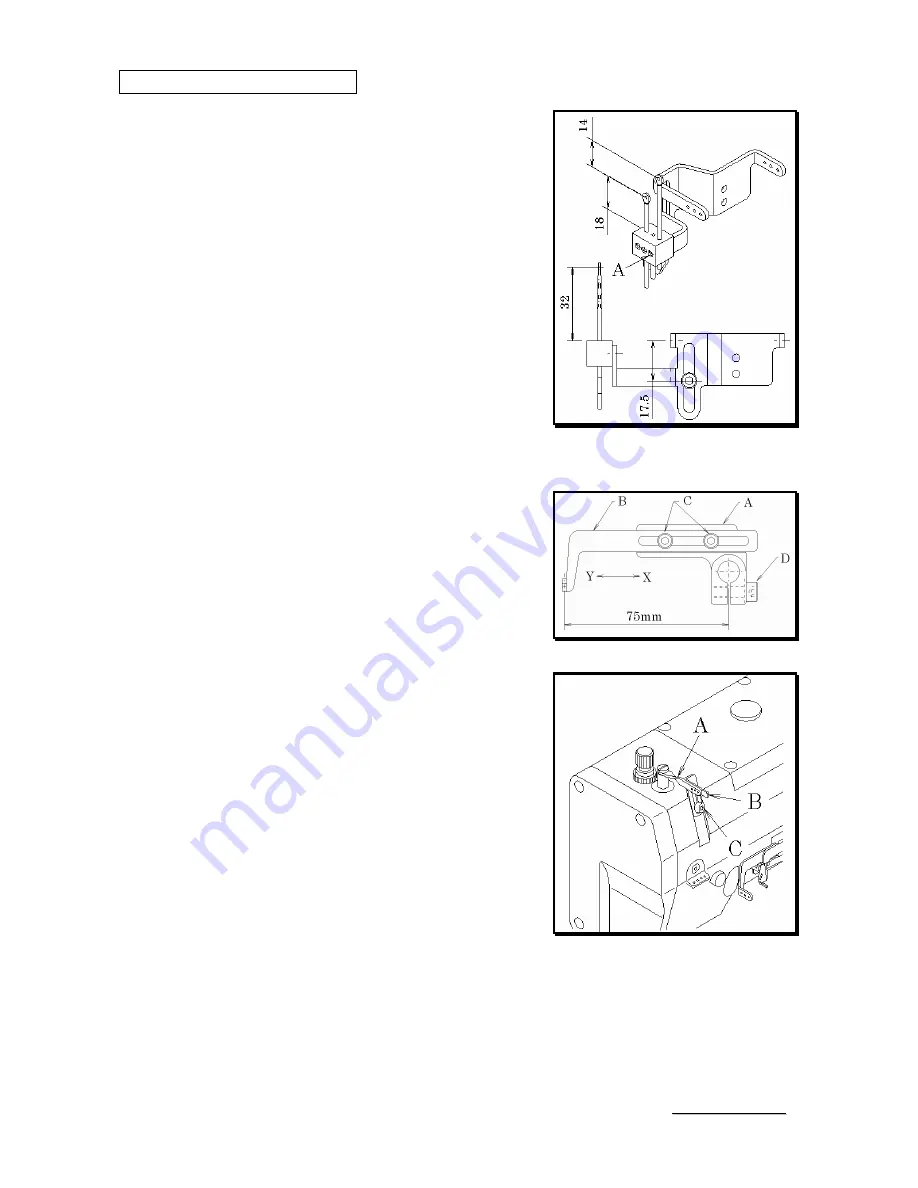

9-1 Position of the needle thread guides

The distance from the center of the eyelet of the

needle thread guide to that of the set screw should

be approximately 17.5mm (see the illustration).

Adjust the height of the thread guides by loosening

screws A and moving each thread guide up or down

(refer to the distances shown in the illustration).

If the stitch formation cannot be changed extremely

by adjusting the height of the thread guides because

of the thread to be used, unravel the thread after

test sewing and adjust the height of the thread

guides while checking the tension of the needle

thread.

9-2 Position of the thread guide on the needle thread take-up

When the needle bar is at the bottom of its stroke,

needle thread take-up bracket A should be level and

the distance from the center of the shaft to the

thread guide of needle thread take-up B should be

75mm. To make this adjustment, loosen screws C

and D. To tighten the needle thread, move needle

thread take-up to Y. To loosen the needle thread,

move needle thread take-up to X.

9-3 Position of the needle thread guard

When the needle bar is at the bottom of its stroke,

the center of the eyelet of thread guide A should be

level with the top surface of needle thread guard B.

In addition, A should be parallel with B.

To adjust the height of needle thread guard B,

loosen screw C and move needle thread guard B up

or down.

To tighten the needle thread, move up B.

To loosen the needle thread, move down B.

■

For cotton threads (non-stretchable threads)

Bring the needle thread guard 2.0mm below the

standard, or remove it. Loosen screw C and move

down the needle thread guard.

■

For woolly threads (stretchable threads)

Raise the needle thread guard as high as possible.

13

B

B

L

L

X

X

s

s

e

e

r

r

i

i

e

e

s

s