15

7777----2 Timing of the retainer looper to the needle

2 Timing of the retainer looper to the needle

2 Timing of the retainer looper to the needle

2 Timing of the retainer looper to the needle

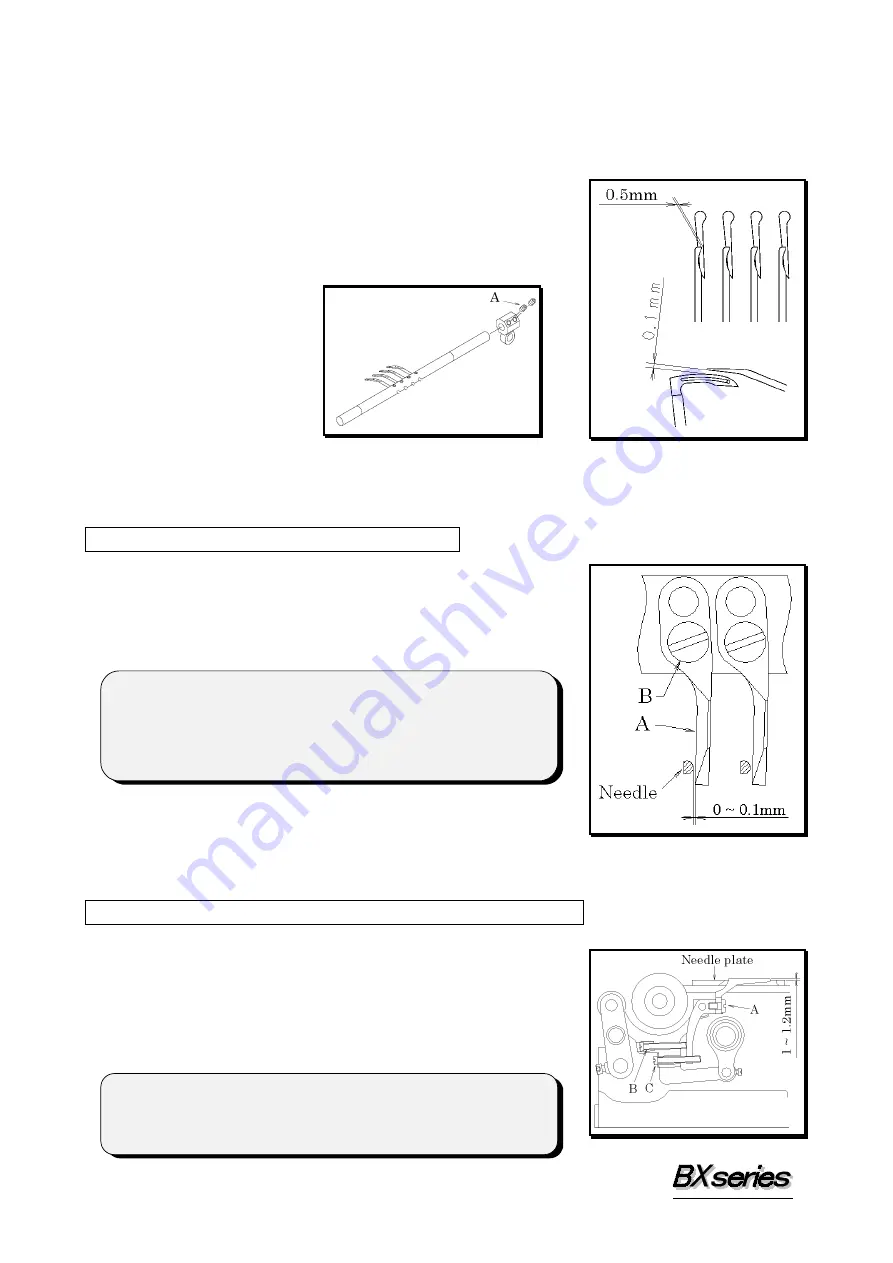

When the needle, moving from the top to bottom of its stroke, enters the triangle of the

looper thread, the retainer looper should be at the extreme right end of its travel.

To adjust the retainer looper left to right, loosen screws A first. With the retainer looper

at the extreme left end of its travel, set the clearance

between the retainer looper and the right side of the

looper at approximately 0.5mm. Then set the clearance

between the retainer looper and the top surface of the

looper blade at 0.1mm. After this adjustment is made,

tighten screws A.

【

8

】

ADJUSTING THE NEEDLE GUARD

8888----1 Position of the needle guard

1 Position of the needle guard

1 Position of the needle guard

1 Position of the needle guard

When the needle is closest to the needle guard, there

should be a clearance 0~0.1mm between the right side of

the needle and needle guard A.

Adjustment is made by loosening screw B.

【

9

】

ADJUSTING THE FEED DOG & STITCH LENGTH

9999----1 Feed dog height & tilt

1 Feed dog height & tilt

1 Feed dog height & tilt

1 Feed dog height & tilt

When the needle bar is at the top of its stroke, the feed

dog teeth should be 1~1.2mm above the top surface of the

needle plate. Adjustment is made by loosening screw A.

Then check to see if the feed dog teeth is parallel with the

top surface of the needle plate. Adjustment is made with

screws B and C.

< Note >

To adjust the standard type of needle guard, after positioning

the looper holder bracket (see 6-1) adjust the looper by

loosening the looper set screw. Then tighten screw B.

< Note >

When adjusting the height of the feed dog, tilt the looper

holder toward the front of the machine.