11-2 Position of the needle thread eyelet

Secure needle thread eyelet C at the bottom end of

the slot.

< Note >

Adjust the needle thread eyelet according to the

thread to be used. To tighten the needle thread,

raise the needle thread eyelet.

11-3 Adjusting the needle thread guard

With the needle bar at the bottom of its stroke, the

top surface of needle thread guard A should be level

and parallel with the centers of the eyes on needle

bar eyelet B.

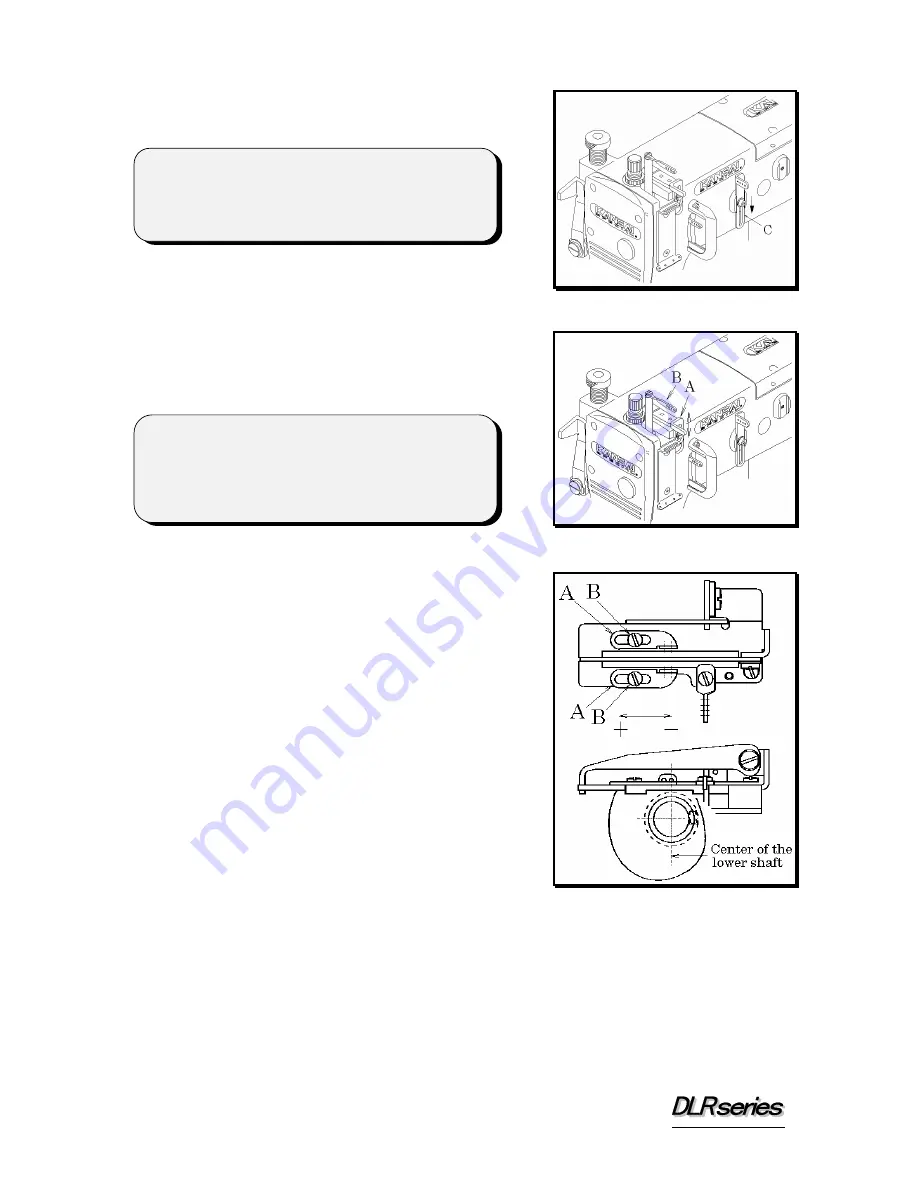

11-4 Adjusting the looper thread eyelets

Align the eyes on looper thread eyelets A with the

center of the lower shaft.

To increase the amount of the looper thread to be

supplied, loosen screws B and move looper thread

eyelets A to the rear of the machine.

To decrease the amount of the looper thread to be

supplied, loosen screws B and move looper thread

eyelets A to the front of the machine.

In case of model 1508SPF, move looper thread

eyelets A fully toward the front of the machine and

secure them with screws B.

Adjust the looper thread eyelets according to the

thread and stitch length to be used.

< Note >

Raising needle thread guard A increases the size of

the needle thread loop. Lowering needle thread

guard A decreases the size of the needle thread

loop.

15